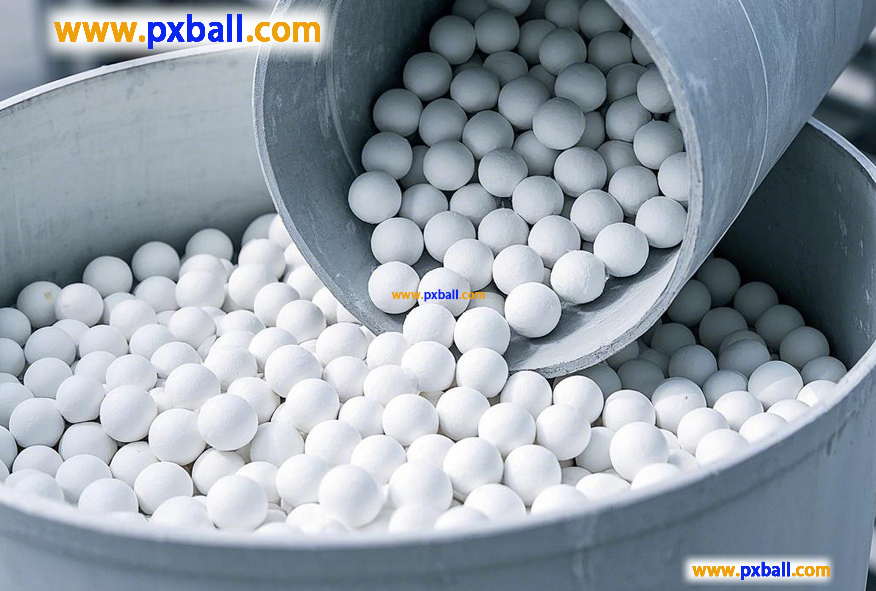

Ceramic support ball definition

Ceramic support ball is a kind of ceramic product which is widely used in many fields such as industry. Alumina (Al₂O₃), silicon oxide (SiO₂) and other ceramic materials were the main components. These ceramic materials have excellent properties such as high hardness, high temperature resistance and chemical corrosion resistance.

Application field of ceramic support ball

** Chemical industry ** : As a covering support material and tower packing for catalysts in the reactor. In chemical reactors, ceramic support balls can evenly disperse the catalyst, ensuring an efficient reaction, while also withstanding the pressure and temperature changes generated during the reaction. For example, in petrochemical catalytic cracking, hydrofining and other units, ceramic support balls play a key role. - Fillers for chemical equipment. In the packed tower, the ceramic support ball can increase the distribution point of gas or liquid, improve the efficiency of mass and heat transfer, and make the chemical production process more stable and efficient.

** Petroleum industry ** : In the petroleum refining process, ceramic support balls can be used to support the catalyst bed to ensure the normal operation of the catalyst. For example, in crude oil hydrocracking, desulfurization, denitrification and other processes, ceramic support balls can provide stable support for the catalyst and improve the selectivity and conversion rate of the reaction.

** Environmental Protection industry ** : In waste gas treatment equipment, ceramic support balls can be used to support adsorption materials, such as activated carbon. When the waste gas passes through the adsorption material, the ceramic support ball can ensure the uniform distribution of the adsorption material and improve the purification effect of the waste gas. In sewage treatment, ceramic support balls can be used as biofilm carriers to provide an attached surface for the growth of microorganisms and promote the biological treatment process of sewage.

** Metallurgical industry ** : In the process of metal smelting, ceramic support balls can be used for support and fillers in high temperature furnaces. For example, in the blast furnace, steel converter and other equipment, the ceramic support ball can withstand high temperature and the impact of the charge, to ensure the gas permeability and the normal reaction in the furnace.

Ceramic support ball size problem

Type of reactor: If it is used for a fixed bed reactor, the size of the ceramic support ball is determined according to the inner diameter of the reactor and the height of the bed. In general, in order to ensure that the gas or liquid can evenly pass through the bed, the diameter of the support ball should be less than 1/10-1/8 of the inner diameter of the reactor.

Supporting object characteristics: When used to support the catalyst, the size of the supporting ball should consider the size of the catalyst particle. Ideally, the diameter of the supporting ball should be 2-3 times the diameter of the catalyst particle. For example, if the catalyst particle diameter is 5 mm, the support ball diameter can be selected to be 10-15 mm. This prevents the catalyst particles from blocking the gap between the support balls and ensures that the gas or liquid can contact the catalyst smoothly.

If used to support fillers: such as lacey rings, pall rings, etc., the size of the support ball should ensure that the filler can be stably placed on it. In general, the diameter of the supporting ball should be greater than 1.5-2 times the maximum size of the packing to provide sufficient supporting area.

Flow: In application scenarios with large flow, in order to reduce fluid resistance and improve flow efficiency, ceramic support balls with appropriate diameters need to be selected. In general, a larger diameter support ball can provide a larger void ratio, making it easier for fluid to pass through. For example, in a chemical distillation tower, if the flow of liquid or gas in the tower is large, choosing a ceramic support ball with a larger diameter (such as 20-30 mm) can reduce the pressure drop of the tower and improve the efficiency of rectification.

Pressure: If there is a high pressure in the application scenario, such as in the high-pressure reactor, it is necessary to choose a larger size and higher strength ceramic support ball. The larger size increases the carrying capacity of the supporting ball and prevents it from being crushed under high pressure. At the same time, the minimum size of the supporting ball should be calculated according to the size of the pressure and the strength of the supporting material.

Ceramic support ball related problems

Aluminum content: alumina ceramic support ball, the alumina content can be changed according to different use requirements, the higher content can reach more than 99%, this high-purity alumina ceramic support ball has better mechanical properties and chemical stability.

Shape and size: Ceramic support balls are usually spherical, because the spherical structure can provide more uniform support in all directions. Diameter range from 3mm to 50mm support ball.

High strength and hardness: The ceramic support ball has a high hardness, and the Mohs hardness is generally between 8-9.

High temperature resistance: can be used in high temperature environment. For example, alumina ceramic support balls can withstand high temperatures of up to 1500-1700 °C.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support