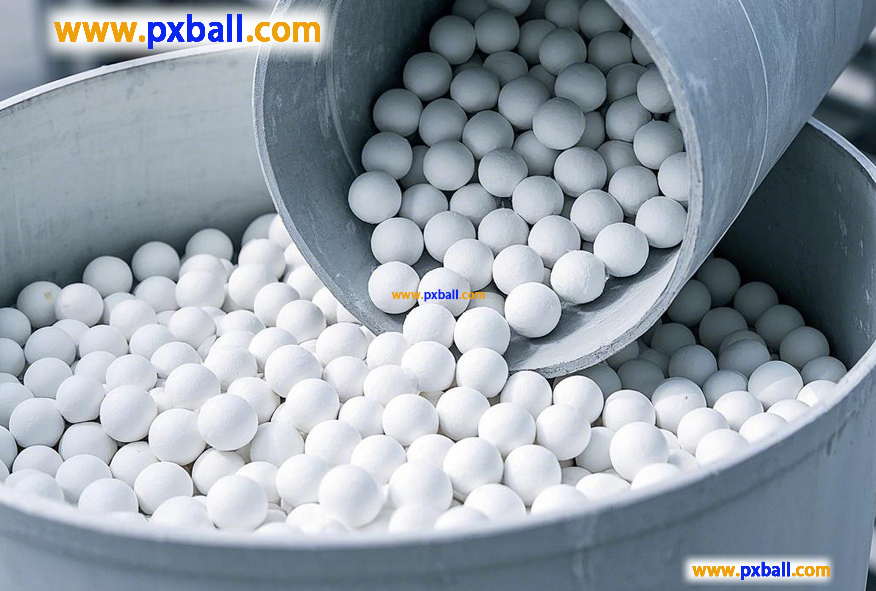

Introduction to Alumina Catalyst Support Balls

Alumina catalyst carrier balls are a material made of alumina in the form of spheres used to carry catalysts. They are used in the petrochemical industry for hydrogenation, dehydrogenation, desulfurization, reforming, and cracking catalytic reactions, such as in the heavy oil hydrogenation catalyst, where alumina catalyst carrier balls can carry hydrogenation catalysts to improve the conversion efficiency and product quality of heavy oil. In the chemical pharmaceutical industry, they are used in drug synthesis reactions as a carrier for catalysts to improve the selectivity and yield of the reaction and reduce the occurrence of side reactions.

Characteristics of Alumina Catalyst Support Balls:

1. High specific surface area: This allows the catalyst to be better dispersed on its surface, increasing the contact area between the catalyst and the reactants, thereby improving the efficiency of the catalytic reaction.

2. Good pore structure: It has rich pores, including micro-pores, meso-pores, and macropores of different pore sizes. These pores not only accommodate the catalyst but also provide channels for the transport of reactants and products, facilitating the reaction.

3. High mechanical strength: In the reaction process, it needs to withstand certain pressure, friction, and impact, so it needs to have high mechanical strength to ensure the stability of its structure and service life.

4. Good chemical stability**: Under various chemical reaction conditions, it can maintain its chemical properties stability, not react with reactants, products, or catalysts, thus affecting the effect of catalytic reaction.

5. Good thermal stability: Under high temperature conditions, it can maintain the stability of its structure and performance, without deformation, sintering, etc., suitable for high-temperature catalytic reactions.

The main components of the alumina catalyst carrier balls are aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂). However, in actual alumina catalyst carrier ball products, in addition to aluminum oxide, there may be small amounts of other components such as silicon (Si), sodium (Na), iron (Fe), and calcium (Ca), but the content of these impurities is usually very low.

How long is the service life of alumina catalyst carrier balls?

The service life of alumina catalyst carrier balls is influenced by a variety of factors and cannot be simply given a fixed duration. Here are some key factors that affect the service life and their impact: temperature, high pressure environment, corrosiveness of reactants and products, the purity and strength of the alumina catalyst carrier balls themselves.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support