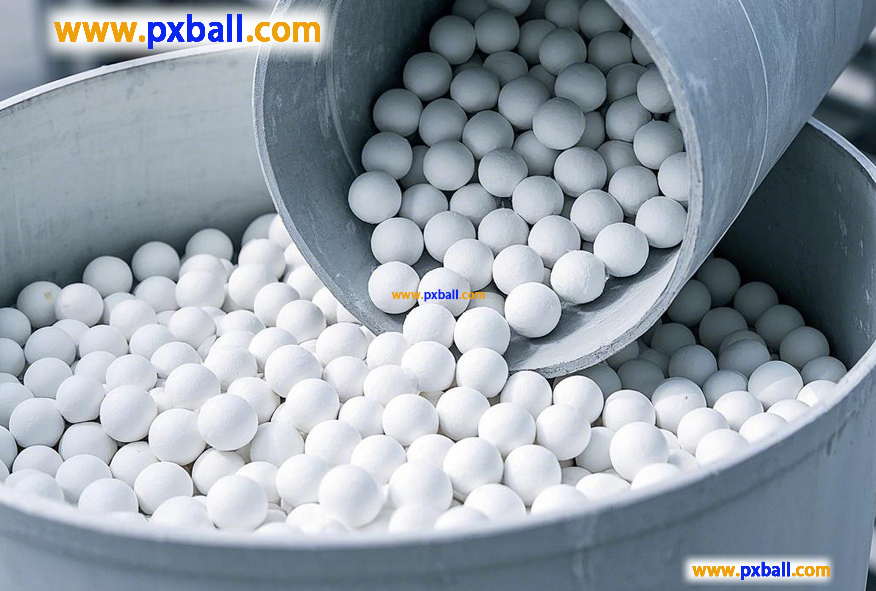

If you are looking for Chinese manufacturers of alumina ceramic balls or seeking answers to related questions about alumina ceramic balls, you can find all the information you need here.

First of all

We are a factory from China that has been specializing in the production of Chinese alumina ceramic balls for many years. Therefore, the quality of our alumina ceramic balls can be more stable and the prices can be more affordable. The main varieties of alumina ceramic balls include: low-alumina ceramic balls, medium-high alumina ceramic balls, perforated ceramic balls, porous ceramic balls, convex and concave inert alumina ceramic balls, etc. The specifications range from 3mm to 50mm. Moreover, when the purchase quantity reaches a certain level, we can customize production according to your requirements.

Contact Information

E-mail: lizhi@pxball.cn

WeChat ID: pxlizhi

Company Website: www.pxball.com

Address: Xiangdong Ceramic Industrial Park, Pingxiang City, Jiangxi Province, China

Classification

According to the content of alumina: They can be classified into low-alumina ceramic balls (with the content of alumina generally ranging from 45% to 60%), medium-alumina ceramic balls (with the content of alumina ranging from 60% to 90%), and high-alumina ceramic balls (with the content of alumina above 90%, such as 92%, 95%, 99%, etc.). The higher the content of alumina, the better the performance of ceramic balls such as hardness, wear resistance, and high-temperature resistance usually is.

Application fields:

Catalyst carriers: In chemical reactions such as petroleum cracking, hydrogenation, and reforming, they serve as carriers for catalysts, providing a large specific surface area for catalysts, enabling the uniform dispersion of active components on their surfaces, thereby enhancing catalyst activity, selectivity, and stability, and prolonging the service life of catalysts.

Reactor packing materials: Used to fill various types of reactors, such as fixed-bed reactors and fluidized-bed reactors, they can evenly distribute gas flow, increase the contact area between gas and liquid, and promote the progress of reactions, helping to improve reaction efficiency and product quality.

Tower packing materials: In distillation towers, absorption towers, extraction towers, etc. of petrochemical plants, they are used as packing materials, which can improve gas-liquid mass transfer and heat transfer effects, enhance separation efficiency, and enable more effective separation of substances with different boiling points.

Sulfur removal and nitrogen removal: In the production process of fertilizers, they are used in sulfur removal and nitrogen removal devices, adsorbing and removing harmful gases such as sulfur dioxide and nitrogen oxides in the gas, reducing pollutant emissions, protecting the environment, and also protecting subsequent production equipment from corrosion.

Shift reaction: In the shift reaction of carbon monoxide, they can serve as supporting and dispersing materials for reaction beds, allowing reaction gases to pass through the bed layer uniformly and come into full contact with the catalyst, thereby increasing the conversion rate of the shift reaction and ensuring the smooth progress of the fertilizer production process.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support