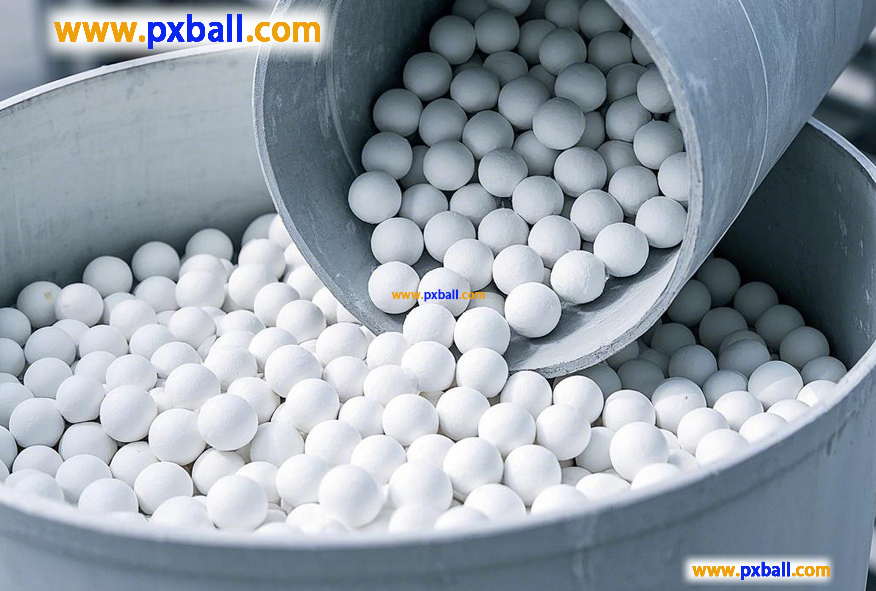

Introduction to Catalyst Carrier Ceramic Balls

Catalyst carrier ceramic balls, also known as chemical filler balls, inert ceramic balls, ceramic support balls, high-purity fillers, are widely used in petrochemical factories, fertilizer factories, alkylbenzene factories, aromatic factories, ethylene factories, natural gas factories, etc. as the bottom filling material for hydrogenation cracking units, refining units, catalytic reforming units, isomerization units, demethylation units, etc. in oil and chemical factories. They are used as support and cover materials for catalysts, molecular sieves, and desiccants in reactors and as tower fillers. Their main function is to increase the distribution points of gases or liquids and support and protect the weakly structured active catalyst.

Characteristics of Catalyst Carrier Ceramic Balls:

High Chemical Stability: able to withstand the corrosion of acids, alkalis and other organic solvents, maintain stability in various complex chemical environments, ensuring that the catalyst carrier itself will not react with the reactants or products unnecessarily during the chemical reaction process, thus affecting the performance of the catalyst and the result of the reaction.

Good High-Temperature Performance: able to maintain structural and performance stability at high temperatures, suitable for high-temperature reaction environments. For example, in the high-temperature industrial processes of petrochemical and refining, the catalyst carrier ceramic balls can

The function of the catalyst carrier ceramic ball:

Dispersing the catalyst: It uniformly disperses the catalyst on its surface and internal pores, enlarging the contact area between the catalyst and the reactants, making the reaction more thorough and efficient. For example, in some large chemical production facilities, using a catalyst carrier ceramic ball can make the catalyst better dispersed in the reaction system, improving the conversion rate and selectivity of the reaction.

Supporting and protecting the catalyst: It provides physical support for the catalyst, preventing the catalyst from breaking or being lost due to external forces. At the same time, due to its high chemical stability, it can avoid the catalyst from reacting with other substances in the reaction system, thus protecting the activity and selectivity of the catalyst.

Facilitating the recovery and reuse of the catalyst: After the reaction is over, the catalyst loaded on the ceramic ball can be separated from the reaction product by simple physical methods, making it convenient to recover and reuse the catalyst and reduce production costs.

Key points for selecting catalyst support ceramic balls:

Chemical stability: The ceramic balls must have high chemical stability in the reaction system to withstand the chemical corrosion of reactants, products, and possible impurities.

Anti-poisoning ability: Some reaction systems may contain substances that poison the catalyst. In such cases, the ceramic ball carrier selected should have good anti-poisoning performance to reduce the impact of poisonous substances on the catalyst.

Porosity: Ceramic balls with high porosity can provide more active sites, which are beneficial for the dispersion of the catalyst and the adsorption of reactants, thereby improving the reaction efficiency.

Mechanical strength: The ceramic balls need to have sufficient mechanical strength to withstand the pressure, impact force, and friction forces during the reaction process, and prevent breaking or wear during the reaction. For ceramic balls used in fluidized bed reactors, the mechanical strength requirement is higher to ensure that they do not break or damage during the fluidization process.

Thermal stability: If the reaction is carried out at high temperatures, the ceramic balls must have good thermal stability to maintain their structure and performance stability at high temperatures. For example, they can be used in the high-temperature catalytic cracking reactions in the petrochemical industry.

Catalyst loading capacity: The ceramic balls should be able to firmly load the catalyst to ensure that the catalyst does not fall off or wash out during the reaction. This is related to the surface properties, pore structure, and interaction between the ceramic balls and the catalyst.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support