Introduction to Catalyst Ceramic Balls

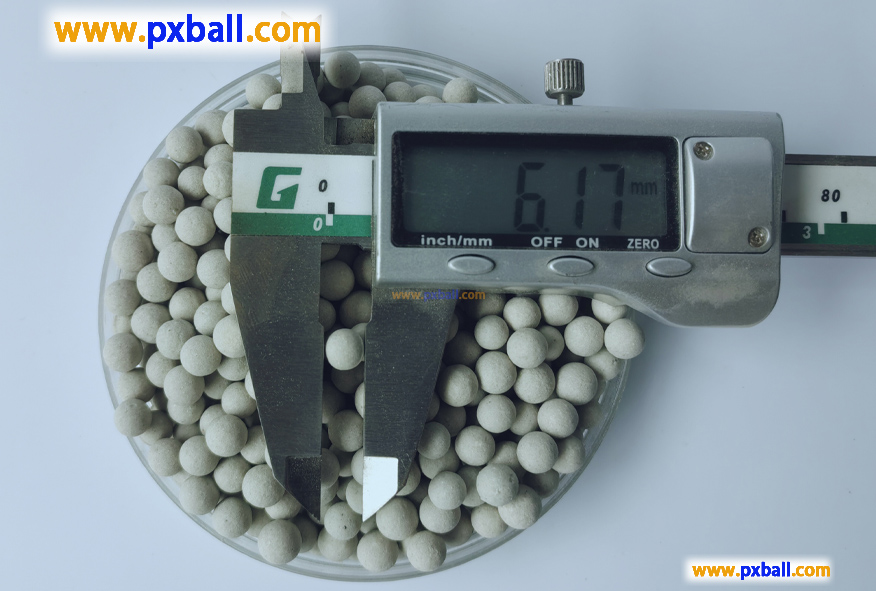

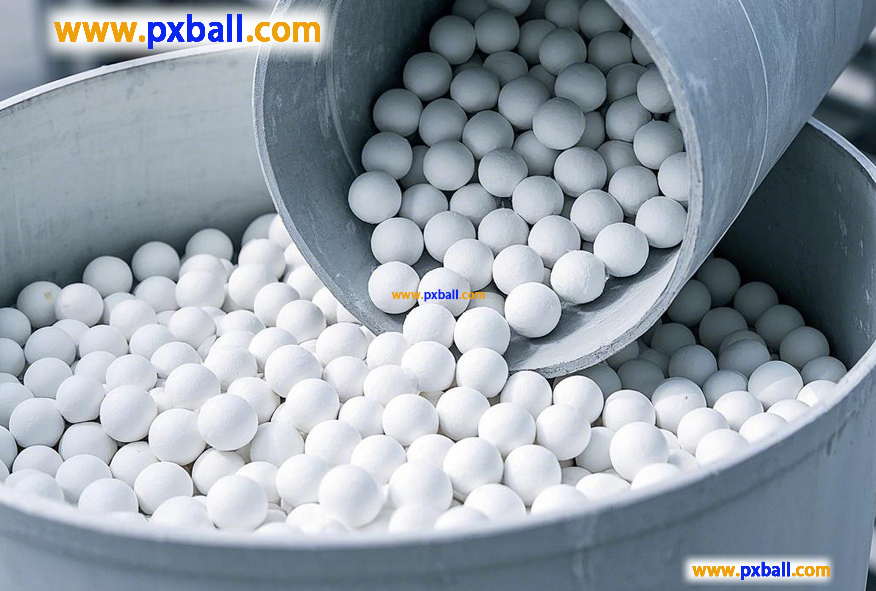

Catalyst ceramic balls are a type of ceramic material used in the field of catalysis, made of alumina powder fired at high temperature to form a shape. It has the characteristics of high temperature and high pressure resistance, low water absorption rate, stable chemical properties, and the ability to withstand the corrosion of acid, alkali and other organic solvents. It can also withstand temperature changes during production. Its main functions are to bear the catalyst and improve the reaction conditions.

Other catalyst ceramic balls

Active ceramic balls: are made by adding a small amount of transition metal oxides to inert ceramic balls. They have the characteristics of high temperature, high pressure, and high mechanical strength of inert ceramic balls, and can be used to filter, disperse gas-liquid cover, support catalysts, and have certain catalytic activity, which can assist in the saturation and denitrification of olefins.

Porous ceramic balls: pores are opened on the surface of inert alumina ceramic balls, which increases their specific surface area and porosity, and has the characteristics of low pressure drop and high flow rate, which can provide more contact area and reaction space for catalytic reaction.

Microporous ceramic balls: are made by creating pores on the surface of inert alumina ceramic balls, with a porosity 20-30% higher than that of ordinary inert alumina ceramic balls, which can filter impurities in oil and can be used for the purification of oil products and the removal of impurities in catalytic reactions.

Characteristics of Catalyst Ceramic Balls:

High Chemical Stability: In various chemical reaction environments, including harsh conditions such as strong acids and bases, the ceramic balls can maintain stable chemical properties and are less likely to react chemically with reactants or products, thus ensuring the purity and selectivity of the catalytic reaction.

Good High-Temperature Performance: They can work stably at high temperatures and are less likely to deform, soften, or crack, meeting the needs of many high-temperature catalytic reactions, such as those in the petrochemical and automotive exhaust treatment industries. In these high-temperature catalytic reactions, the catalyst ceramic balls can maintain good performance.

High Mechanical Strength: They have high mechanical strength and can withstand the force of pressure, friction, and impact during the catalytic reaction process, are less likely to break or wear, and ensure the long-term stable use of the catalyst.

Large Specific Surface Area: Some types of catalyst ceramic balls have a large specific surface area, such as open-pored ceramic balls and microporous ceramic balls, which allow the catalyst to be better dispersed on their surface, increasing the contact area between the catalyst and the reactants and improving the efficiency of the catalytic reaction.

Application Fields

Petrochemical Industry: Used as catalyst carriers and fillers in refining, catalytic cracking, hydrogenation cracking, etc. processes, which can improve the reaction efficiency and product quality.

Environmental Protection Field: Used as catalyst carriers or fillers in environmental protection technologies such as waste gas treatment and wastewater treatment, to remove harmful substances in waste gases such as nitrogen oxides and sulfur oxides, and purify organic pollutants in wastewater.

Energy Field: Used as catalyst carriers or electrode materials in energy conversion technologies such as fuel cells and solar cells, to participate in the energy conversion and storage process.

Fine Chemical Industry: Used in catalytic reactions for synthesizing fine chemicals such as pharmaceuticals, perfumes, and dyes, to improve the selectivity and yield of the reaction, and reduce production costs.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support