Definition

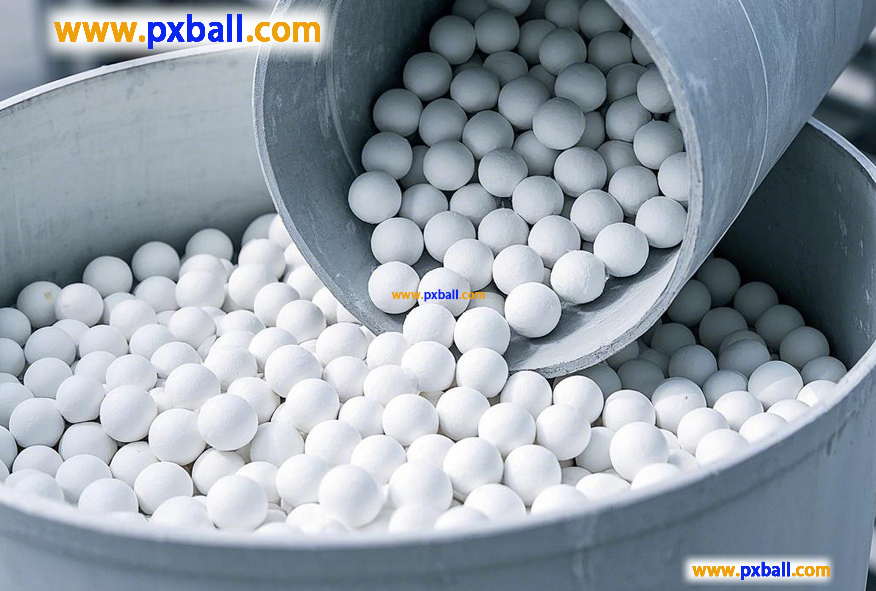

Ceramic catalyst support balls are spherical objects mainly made of ceramic materials and used to support catalysts. They play a significant role in fields such as chemical engineering, petroleum, and environmental protection.

function; role; effect; influence

Supporting catalyst: It provides physical support for the catalyst, keeping it in a certain shape and height within the reactor, preventing the catalyst particles from accumulating, moving or being lost due to gravity or fluid impact force, ensuring the catalyst is evenly distributed during the reaction process and fully exerting its catalytic effect.

Improving material distribution: It increases the distribution points of gas or liquid, making the reaction materials evenly distributed in the catalyst bed, enhancing the contact efficiency between the reactants and the catalyst, promoting the thorough progress of the reaction, and reducing problems such as local overheating and incomplete reaction caused by uneven material distribution.

Protecting the catalyst: It can filter and intercept impurities and particles in the reaction materials, preventing them from entering the catalyst bed, avoiding catalyst poisoning, clogging or wear, and extending the service life of the catalyst.

Characteristics

Excellent chemical stability: Ceramic materials have outstanding chemical stability, being resistant to erosion by acids, alkalis, salts and other chemical substances. They remain stable in various complex chemical environments and are unlikely to undergo chemical reactions with reactants or products, thus ensuring the stability and reliability of catalytic reactions.

Strong high-temperature resistance: They can operate normally under high-temperature conditions, withstand the high-temperature environment inside the reactor, and are unlikely to deform, melt or be damaged, ensuring their continuous role in supporting and protecting the catalyst during high-temperature catalytic reactions.

High mechanical strength: They possess high compressive strength and wear resistance, capable of withstanding significant pressure and friction. During long-term use in the reactor, they are unlikely to break or wear out, guaranteeing their reliability in supporting the catalyst and withstanding fluid impact.

Reasonable pore structure: They have uniform pore distribution and appropriate pore size, which is conducive to the diffusion of the catalyst and the adsorption of reactants, enabling efficient reactions on the catalyst surface and enhancing the efficiency of catalytic reactions.

Application fields

Petroleum and chemical industry: In the petroleum refining process, such as catalytic cracking, hydrorefining, and reforming reactions, ceramic catalyst support balls are used to support and protect the catalysts, improving reaction efficiency and product quality.

Coal chemical industry:In reactions such as coal gasification and syngas conversion, ceramic catalyst support balls can help the catalysts operate stably in high-temperature, high-pressure, and highly corrosive environments.

Environmental protection field: In environmental protection projects such as waste gas treatment and wastewater treatment, ceramic catalyst support balls are used to support catalysts for the catalytic degradation of pollutants, such as in the purification of vehicle exhaust, denitrification of industrial waste gas, and catalytic oxidation in wastewater treatment.

Fine chemical industry: In various fine chemical product synthesis reactions, such as in the pharmaceutical, pesticide, and fragrance industries, ceramic catalyst support balls also play an important role, helping to improve the selectivity and yield of the reactions.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support