Introduction

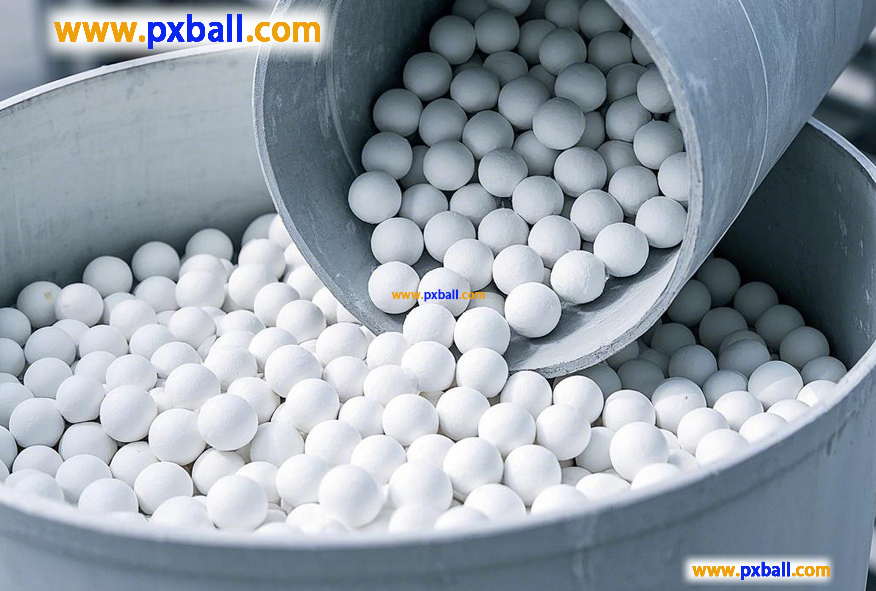

Inert ceramic ball catalyst support is widely used in the fields of petroleum, chemical, pharmaceutical, etc., mainly used as a catalyst support and filler. It is an inactive ceramic ball that does not possess catalytic activity but has high thermal stability, chemical stability, and mechanical strength. Many chemical reactions require the use of catalysts to accelerate reaction rates and improve yields. Inert ceramic balls serve as catalyst carriers, providing suitable surface and pore structures that enable the catalyst to be better dispersed on the carrier, thereby improving the utilization rate and reaction efficiency of the catalyst.

Characteristics of Inert Ceramic Ball Catalyst Carrier:

Chemical Stability: Inert ceramic balls are made of inert materials, which have stable chemical properties and are not easily reacted with acids, bases, salts, and various organic solvents. They can be used stably in corrosive environments such as acid-base for a long time, and can adapt to the harsh chemical environment in the petrochemical and fertilizer industries, protecting the catalyst from corrosion.

Non-poisoning: It will not react with the reactants or products in an unnecessary chemical reaction, thus avoiding the poisoning and inactivation of the catalyst due to the adsorption or reaction of chemical substances. It can extend the service life of the catalyst.

High Strength and Hardness: It has high mechanical strength and hardness, which can withstand greater pressure and friction. It is not easy to break or wear in the reactor, which can ensure the stability and integrity of the catalyst in the reaction process and reduce the problems of catalyst loss and reactor blockage caused by carrier breakage.

High Temperature Resistance: It can withstand the high-temperature catalytic reaction and is not easy to melt or deform. It can maintain the stability of its physical and chemical properties at high temperatures and is suitable for various high-temperature catalytic reactions, such as petroleum cracking and reforming.

Good Thermal Conductivity: It can quickly transfer heat to the surrounding environment and maintain the stability of its surface temperature, which is beneficial to the heat transfer and temperature control in the reaction process and can improve the efficiency and selectivity of the reaction.

Low Friction Coefficient: Its surface is smooth and has a low friction coefficient, which can reduce frictional wear with other materials and reduce energy consumption. It can improve the efficiency of the reactor.

Large Specific Surface Area: The larger specific surface area can provide more active sites, increase the loading of the catalyst, and thus improve the utilization rate and reaction efficiency of the catalyst.

The Role of Inert Ceramic Ball Catalyst Carrier:

Improve Reaction Efficiency: As a carrier for the catalyst, it can evenly disperse the catalyst on its surface and pores, increasing the contact area between the catalyst and the reactants, thus improving the reaction rate and efficiency, lowering the activation energy of the reaction, and allowing the reaction to proceed under milder conditions, saving energy and costs.

Protect the Catalyst: It serves as a support and cover for the catalyst in the reactor, buffering the impact of liquid and gas entering the reactor on the catalyst, preventing the catalyst from being damaged by the erosion, wear, or compression of the fluid, prolonging the service life of the catalyst, improving the stability and economic efficiency of production.

Improve Fluid Distribution: It can improve the distribution of liquid and gas in the reactor, making the reactants flow more evenly in the reactor, avoiding local overheating and uneven concentration problems, improving the selectivity of the reaction and product quality, and reducing the occurrence of side reactions.

In summary, inert ceramic ball catalyst carrier with its excellent chemical stability, physical properties and structural characteristics plays an important role in catalytic reactions in many fields such as petrochemical, coal chemical, fine chemical, pharmaceutical, etc. It can improve the reaction efficiency, reduce the cost and extend the service life of the catalyst, and is an indispensable catalyst carrier material.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support