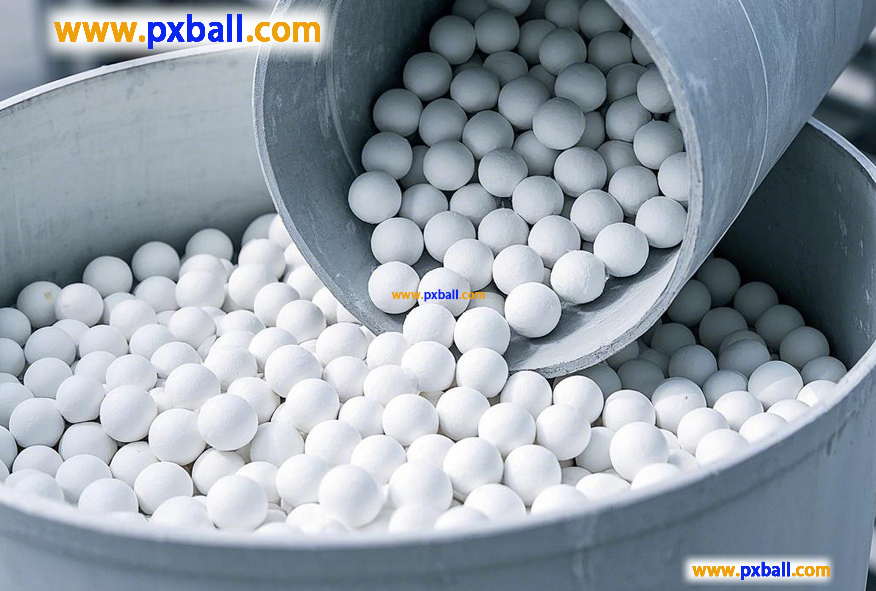

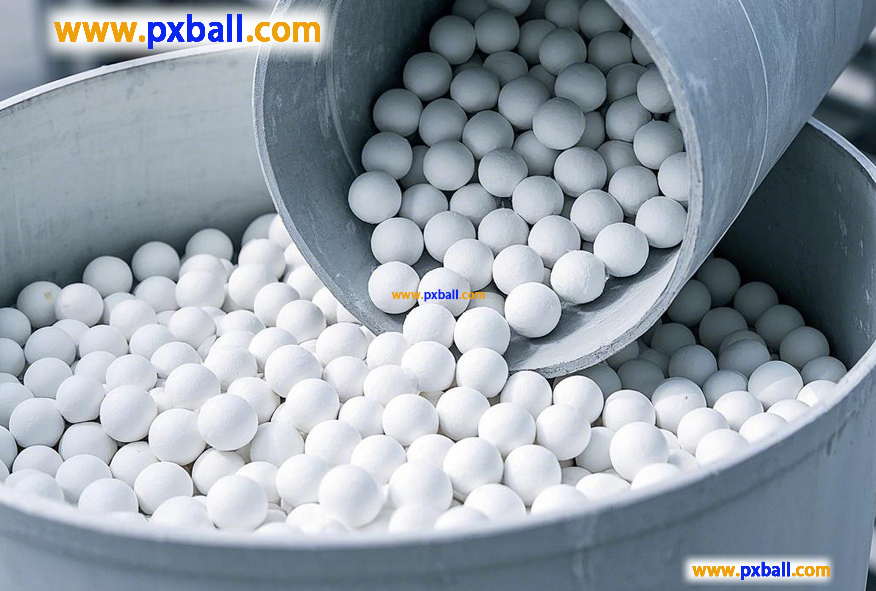

Definition

Catalytic bed ceramic balls refer to inert ceramic balls used in catalytic beds. They are ceramic products with high strength, good chemical stability, and excellent thermal conductivity. They play significant roles in catalytic beds such as supporting and dispersing catalysts, optimizing fluid distribution, protecting catalysts, assisting heat transfer and distribution, and improving reaction efficiency and selectivity. During filling, many precautions need to be taken to ensure their optimal performance.

Chemical composition:

Al2O3+SiO2 | Al2O3 | SiO2 | Fe2O3 | MgO | K2O+Na2O+CaO | Other |

>92% | 17-23% | 68-73% | <1% | <0.5% | <4% | <0.5% |

Leach able Fe2O3 is less than 0.1%.

Factors Affecting the Service Life of Catalytic Bed Ceramic Balls

Inert Ceramic Balls Quality: The purity of the material and crystal structure of ceramic balls can affect their performance. Ceramic balls with high purity and stable crystal structure have stronger corrosion and wear resistance and a longer service life.

Manufacturing Process: The molding process and sintering temperature during production are crucial to the quality of ceramic balls. Precise control of process parameters can enable ceramic balls to have appropriate density, porosity, and mechanical strength.

Operating Temperature: Excessive or fluctuating operating temperatures will cause thermal stress in ceramic balls, leading to cracking and deformation. For example, in some high-temperature catalytic reactions, if the temperature exceeds the tolerance range of ceramic balls, it will accelerate their aging and damage.

Operating Pressure: Excessive system pressure or large fluctuations in pressure may cause ceramic balls to bear excessive pressure and break.

Fluid Flow Rate: Excessive fluid flow rate will increase the erosion and wear of ceramic balls, reducing their service life.

Chemical Corrosivity: If the reaction medium has strong corrosivity, it will react with ceramic balls, eroding the surface of ceramic balls and reducing their performance.

Catalyst Properties: Some catalysts may interact with ceramic balls, affecting their performance. For example, some catalysts with strong oxidizing or acidic properties may react with the components on the surface of ceramic balls.

Catalyst Loading Method: The uniformity and firmness of catalyst loading on ceramic balls will also indirectly affect the service life of ceramic balls. If the catalyst loading is not uniform, it will cause local over-reaction of ceramic balls, accelerating aging.

Uniform Loading: Inhomogeneous loading of ceramic balls will result in uneven fluid distribution, causing local ceramic balls to be subjected to excessive force or severe erosion, shortening their service life.

Loading Density: Excessive loading density will cause ceramic balls to be squeezed too tightly between each other, which is prone to breakage during operation due to mutual squeezing; too small loading density will cause ceramic balls to shake within the bed layer, also causing wear and damage.

Detailed size &Crush strength

Size | Crush strength | |

Kg/particle | KN/particle | |

1/8''(3mm) | >35 | >0.35 |

1/4''(6mm) | >60 | >0.60 |

3/8''(10mm) | >85 | >0.85 |

1/2''(13mm) | >185 | >1.85 |

3/4''(19mm) | >487 | >4.87 |

1''(25mm) | >850 | >8.5 |

1-1/2''(38mm) | >1200 | >12 |

2''(50mm) | >5600 | >56 |

The Functions of Ceramic Balls in the Catalytic Bed

Provide stable support: Offer a solid foundation for the catalyst, enabling it to be evenly distributed throughout the catalytic bed. This prevents the catalyst from accumulating or sinking due to its own weight or fluid impact, ensuring that the catalyst maintains a stable position and shape throughout the reaction process, which is beneficial for improving the utilization rate of the catalyst and the efficiency of the catalytic reaction.

Promote uniform dispersion: The inert ceramic balls can evenly separate the catalyst particles, maintaining an appropriate distance between them, increasing the contact area between the catalyst and the reactants, allowing the reactants to fully contact the catalyst surface, thereby enhancing the reaction rate and effect.

Uniform distribution of fluids: Enable the fluids (including gases and liquids) entering the catalytic bed to be evenly distributed across the entire cross-section of the catalytic bed, avoiding phenomena such as flow deviation and channeling. Ensure a good flow state of the fluids in the catalytic bed, allowing the reactants to uniformly contact and react with the catalyst, improving the uniformity and conversion rate of the reaction, and reducing situations where local reactions are excessive or insufficient due to uneven fluid distribution.

Improve fluid dynamics: Through its specific shape and packing method, change the flow path and velocity distribution of the fluids, forming a good turbulent state in the catalytic bed, enhancing the mass transfer and heat transfer processes between the fluids and the catalyst surface, facilitating the diffusion of reactants to the catalyst surface and the desorption of products from the catalyst surface, further improving the reaction efficiency.

Buffer fluid impact: Can buffer the direct impact of the fluids entering the catalytic bed on the catalyst, reducing the scouring and abrasion of the fluids on the catalyst, and preventing the fragmentation and pulverization of catalyst particles due to mutual friction or collision with the reactor wall, protecting the integrity and activity of the catalyst, prolonging the service life of the catalyst, and reducing the frequency and cost of catalyst replacement.

Isolate harmful substances: In some reaction systems, there may be a small amount of impurities or harmful substances. The inert ceramic balls can play a certain role in isolating and blocking these substances from directly contacting the catalyst, preventing catalyst poisoning or contamination, maintaining the activity and selectivity of the catalyst, and ensuring the stable progress of the catalytic reaction.

Good thermal conductivity: Possessing good thermal conductivity, it can quickly transfer the heat generated during the catalytic reaction, preventing local overheating in the catalytic bed, avoiding catalyst activity decline, deactivation or occurrence of side reactions due to high temperature. At the same time, it can evenly transfer the external heat to the catalyst and reactants, making the temperature distribution in the entire catalytic bed more uniform, maintaining the catalytic reaction within an appropriate temperature range.

Thermal stability guarantee: With its own thermal stability, it can maintain stable physical and chemical properties in high-temperature environments, not deforming, softening or melting due to temperature changes, thereby ensuring the integrity and stability of the catalytic bed structure, providing reliable support and reaction environment for the catalytic reaction.

Synergistic promotion of reactions: Through the above multiple functions, it creates favorable conditions for the catalytic reaction, enabling reactants to more fully contact and react with the catalyst, improving the conversion rate and efficiency of the reaction. At the same time, the uniform fluid distribution and temperature field are conducive to controlling the reaction path and rate, reducing the occurrence of side reactions, thereby improving the selectivity of the reaction, and increasing the yield of the target product.

Extend reaction cycle: Due to the ability of inert ceramic balls to protect the catalyst and optimize reaction conditions, the entire catalytic reaction system can operate in a more stable state, reducing the occurrence of reaction interruptions or efficiency decline due to catalyst deactivation, uneven fluid distribution, and other issues, thereby extending the stable operation cycle of the catalytic reaction, improving production efficiency and economic benefits.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support