Brief introduction

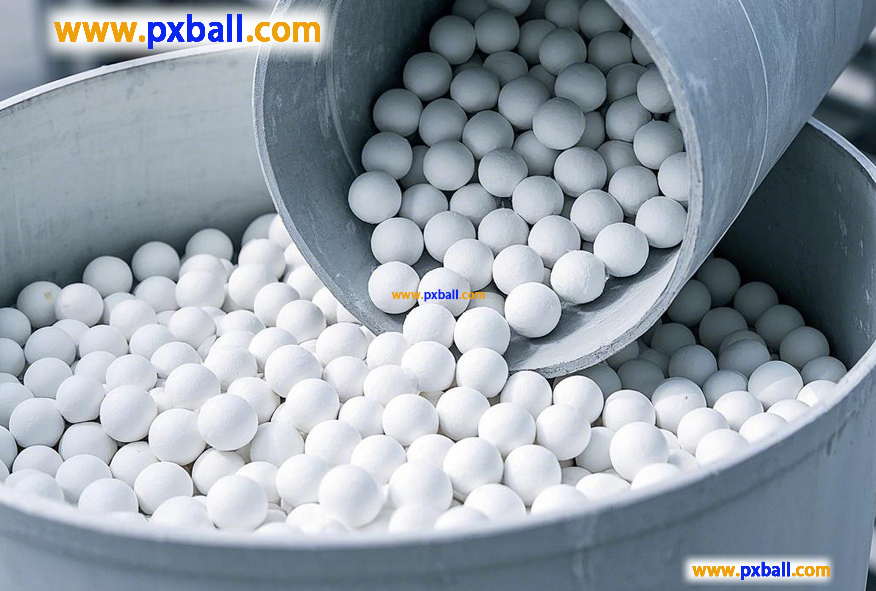

Ceramic ball catalyst is a kind of catalyst in which the active component of catalyst is loaded on the ceramic ball support. As a carrier, the ceramic ball provides the physical support structure for the catalyst, and the active component is the key part of catalysis. Ceramic ball carrier usually has good chemical stability, thermal stability and mechanical strength.

Ceramic ball catalysts are classified by material

Ordinary alumina ceramic ball: has good chemical stability and a certain mechanical strength. It has a moderate specific surface area and can be used to support a variety of catalyst active ingredients. For example, in some chemical synthesis reactions, ordinary alumina ceramic balls can be loaded with metal oxide catalysts to catalyze simple REDOX reactions.

High purity alumina ceramic ball: high purity alumina ceramic ball (such as more than 99% purity), its high temperature resistance and chemical stability is more excellent. In high-temperature catalytic reactions, such as high-temperature sintering reactions in the preparation of some advanced ceramic materials, high-purity alumina ceramic balls as catalyst carriers can withstand higher temperatures to ensure the activity and stability of the catalyst.

Factors influencing the service life of ceramic ball catalyst

Temperature: In high temperature environment, the stability of ceramic ball catalyst will be tested.

Pressure: The high pressure environment will create physical pressure on the ceramic ball.

Chemical environment: The chemical properties of the reactants and products have a great influence on the life of the ceramic ball catalyst.

Active ingredient loss: The catalyst active ingredient loaded on the ceramic ball may be lost during the reaction for various reasons. Poisoning phenomenon: Some impurities or reaction byproducts may be adsorbed on the active site of the ceramic ball catalyst, resulting in poisoning.

Fluid erosion: In fluidized bed reactors or fixed-bed reactors with higher flow rates, fluid erosion of ceramic balls can cause surface wear.

Particle collisions: In some reactors, collisions occur between ceramic spheres or between ceramic spheres and other substances.

effect

Improve reaction efficiency: The ceramic ball has a large specific surface area, especially when the ceramic ball has a rich pore structure, the active component can be highly dispersed in its surface and internal pores.

Reduce the activation energy of the reaction: ceramic ball catalyst can change the reaction process and reduce the activation energy of the reaction.

Enhance catalyst stability: the ceramic ball carrier itself is chemically stable and can resist the corrosion of chemical substances such as acid and alkali.

Thermal stability: The ceramic ball can withstand high temperature environment, maintain structural integrity in high temperature reaction, and ensure that the active components of the catalyst do not agglomerate or sintering.

Mechanical stability: The mechanical strength of the ceramic ball is high, and it can withstand certain pressure and friction during the reaction process.

Improve the selectivity of the reaction: by selecting the appropriate active component and the structure of the ceramic ball carrier, the reaction can be controlled in the desired direction and the selectivity of the target product can be improved.

Inhibition of side reactions: Ceramic ball catalyst can inhibit side reactions through the synergistic effect of its active component and carrier. In organic synthesis, side reactions often reduce the purity and yield of the target product.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support