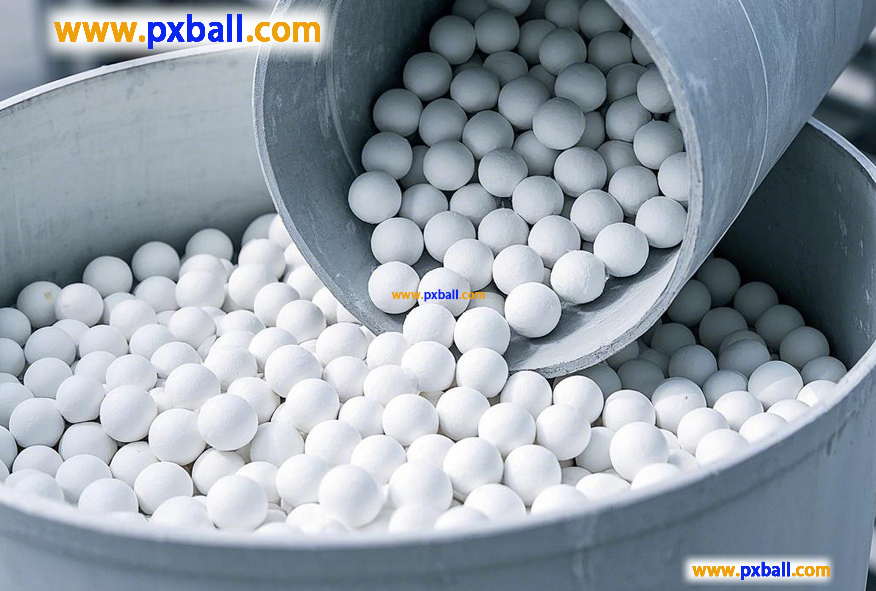

Alumina support ball is a kind of spherical object with alumina as the main component, which plays an important role in many fields.

First, characteristics **

1. High strength: with high mechanical strength, it can withstand greater pressure and is not easy to break. This allows it to play a stable supporting role in a variety of industrial environments.

2. High hardness: high hardness, able to resist wear and scratching, to ensure that its shape and performance are maintained during long-term use.

3. High temperature resistance: can work stably in high temperature environment, not easy to deform or soften. This characteristic makes it widely used in high temperature reactor, kiln and other equipment.

4. Good chemical stability: It has good resistance to most chemical substances and is not easy to be corroded. This makes it reliable for use in chemical, petroleum and other industries.

** II. Application field **

1. Catalyst carrier: as the support body of the catalyst, it provides a stable structure and good dispersion for the catalyst. The high surface area and porosity of alumina support ball can increase the contact area between catalyst and reactant and improve the catalytic reaction efficiency.

2. Chemical industry: In chemical reactors, it is used to support the catalyst bed to ensure the uniform distribution of reactant fluids. At the same time, it can also be used as a filler to improve the heat and mass transfer performance of the equipment.

3. Petroleum industry: In refining and petrochemical processes, alumina support balls can be used to support and fix catalysts, and play an important role in hydrogenation reactors, reforming reactors and other equipment.

4. Environmental protection: used in waste gas treatment equipment as a catalyst carrier to help remove harmful substances in waste gas. For example, in the automobile exhaust purification device, the alumina support ball can carry the precious metal catalyst, effectively reducing the emission of pollutants in the exhaust.

The service life of the alumina support ball is affected by a variety of factors, in general, its service life ranges from 1 to 5 years.

1. Factors affecting service life

Use environment

Temperature: In a high temperature environment, the alumina support ball may undergo phase change, softening or strength reduction, thereby shortening the service life. If it is in extremely high temperatures for a long time, it may need to be replaced in a few months. On the contrary, in a relatively low temperature and stable environment, the service life will be extended accordingly.

Chemical corrosion: If there is strong acid, strong alkali or other corrosive substances in the use environment, it will cause erosion of the alumina support ball and shorten its life. For example, in a strongly acidic environment, alumina may react with the acid, causing damage to the surface of the sphere, which in turn affects its overall performance.

Load pressure: If the support ball is subjected to too much pressure, it may cause the ball to deform, crack or reduce strength. When used in a high pressure environment, it is necessary to choose a higher strength support ball, otherwise its service life may be greatly shortened. For example, in some high-pressure reactors, the support ball needs to withstand greater pressure, and if it is not selected properly, it may need to be replaced in a few months.

Alumina content: Generally speaking, the higher the alumina content, the better the strength, hardness and wear resistance of the support ball, and the service life will be extended accordingly. High purity alumina support balls may last for several years in the right environment.

Manufacturing process: Advanced manufacturing process can make the support ball have a more uniform structure, higher density and better performance stability, thus extending the service life. For example, the support ball manufactured by the isostatic pressing process has a denser internal structure, higher strength and relatively long service life.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support