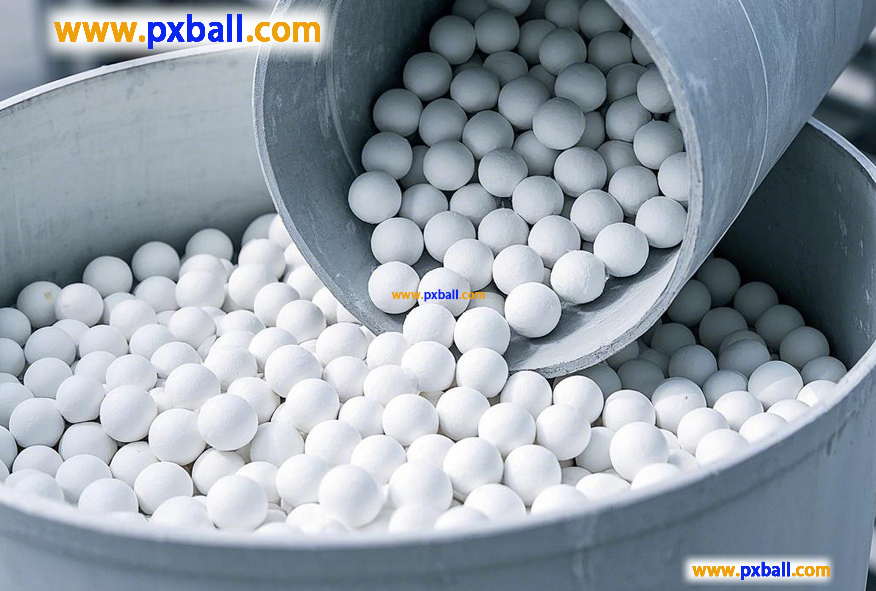

Ceramic balls for catalysts are a widely used material in industries such as petroleum, chemical, fertilizer, natural gas, and environmental protection, mainly used to support and cover catalysts. Here are some detailed information about ceramic balls used for catalysts:

1. Type:

Ordinary ceramic balls: have relatively low aluminum content, with alumina content generally around 17% -23%. They have certain mechanical strength and chemical stability, and can be used in catalytic reaction scenarios where performance requirements are not particularly high.

Medium alumina ceramic balls: with an alumina content between 23% and 47%, their comprehensive performance is superior to ordinary ceramic balls, and they can withstand higher temperatures and pressures. They exhibit good stability in complex chemical reaction environments.

High alumina ceramic ball: With a high alumina content, usually above 47%, it has higher strength, hardness, and high temperature resistance, making it suitable for high-temperature and high-pressure catalytic reaction environments that require high performance of ceramic balls.

99% pure aluminum ceramic ball: With an alumina content of about 99%, it is a high-performance ceramic ball product with extremely excellent high temperature resistance, corrosion resistance, and wear resistance. It is commonly used in high-end catalytic reactions that require extremely high catalyst protection.

2. Characteristics:

High mechanical strength: Ceramic balls for catalysts can withstand the pressure inside the reactor and the weight of the catalyst, and are not easily broken or deformed during long-term use, ensuring the stability of the catalyst bed.

Good chemical stability: It is inert and not easily reacted with catalysts and other substances in the reaction system, and will not interfere with the catalytic reaction-

High temperature resistance: Ceramic balls used as catalysts can maintain stable physical and chemical properties in high-temperature environments, and can withstand the high temperatures generated during catalytic reactions. The maximum operating temperature can generally reach 900 ℃ or above.

Good thermal conductivity: It can effectively conduct heat, help maintain the temperature uniformity of catalytic reactions, and improve reaction efficiency.

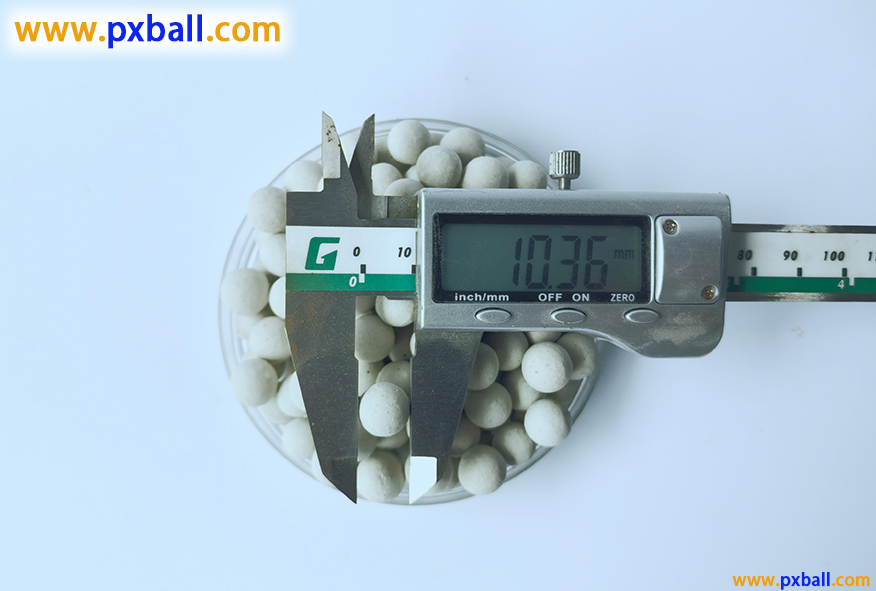

Uniform particle distribution: with regular shape and uniform size, it is conducive to the transmission of fluids and the uniform progress of reactions.

3. Function:

Supporting function: Ceramic balls are used to provide support for the catalyst, allowing it to be evenly distributed in the reactor, increasing the contact area between the catalyst and reactants, and improving the efficiency of the catalytic reaction.

Coverage protection function: It can cover the surface of the catalyst to prevent contamination and erosion by impurities in the reactants, while also buffering the impact of liquids and gases entering the reactor on the catalyst, reducing wear and deactivation of the catalyst, and extending its service life- Improving fluid distribution: The presence of ceramic balls can improve the distribution of liquid and gas in the reactor, allowing the reactants to come into contact with the catalyst more evenly, thereby increasing the selectivity and conversion rate of the reaction.

Ceramic Ball for Catalytic Bed

China Alumina Ceramic Ball

china ceramic ball catalyst

ceramic catalyst support balls

inert ceramic balls catalyst support

Inert filling ceramic ball

ceramic ball catalyst

ceramic balls for catalyst support