Testing the temperature resistance of inert ceramic balls has the following important reasons:

** First, ensure safe use **

In many industrial applications, inert ceramic balls are exposed to different temperature environments. If it is not clear about its temperature resistance, it may break and damage in a high temperature environment, resulting in safety accidents. For example, in chemical production, if the ceramic ball is unable to withstand high temperatures and cracks, it may lead to contamination of the reaction system, and even cause an explosion and other dangerous situations. In the lining materials of some high-temperature furnaces, if the ceramic ball has poor temperature resistance, it may be broken and fall off during use, posing a threat to the structural stability of the furnace, and also bringing hidden dangers to the safety of the operator.

Two, ensure the stability of the process **

Different industrial processes have specific temperature requirements. Understanding the temperature resistance of inert ceramic balls can ensure their stable function under specific process conditions. For example, in catalytic reactions in the petrochemical field, the catalyst usually requires a carrier to maintain its activity and stability. Inert ceramic ball as a common catalyst carrier, if it can not withstand the temperature change during the reaction process, it may lead to catalyst deactivation, affect the efficiency and selectivity of the reaction, and then affect the stability of the entire production process and product quality.

** Three, optimize equipment performance **

In some high-temperature equipment, such as heat exchangers, incinerators, etc., inert ceramic balls may be used as filling materials or filter media. Testing its temperature resistance can help select the right ceramic ball to optimize the performance of the equipment. If the temperature resistance of the ceramic ball does not match the working temperature of the equipment, it may lead to the reduction of the heat transfer efficiency of the equipment, the increase of resistance, and even the shortening of the service life of the equipment.

** Fourth, reduce costs **

By testing the temperature resistance of inert ceramic balls, the actual needs can be more accurately met when selecting materials, and waste caused by improper material selection can be avoided. For example, if you choose a ceramic ball with high temperature resistance, it may increase unnecessary costs; If the selected ceramic ball has insufficient temperature resistance, it may lead to frequent replacement of materials and increase maintenance costs. At the same time, understanding the temperature resistance of ceramic balls also helps to rationally design equipment and processes, improve resource utilization efficiency, and reduce the overall production cost.

Porcelain Ball Manufacturers

Ceramic Ball Manufacturers

ceramic alumina balls

Handmade ceramic balls

Production Method of Inert Ceramic Balls

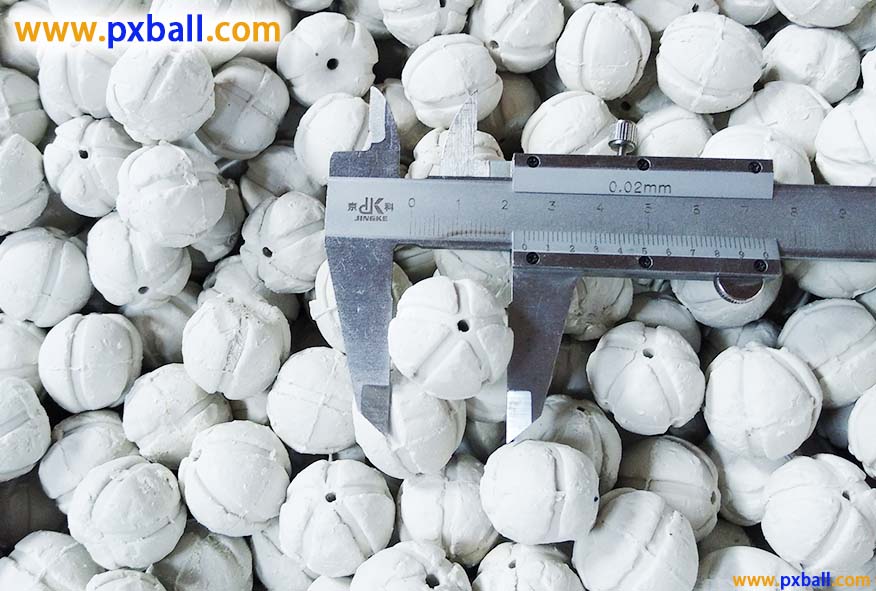

ceramic ball with hole

high teperature ceramic balls

ceramic ball with holes