Introduction to ceramic packing balls

Ceramic packing ball is a kind of material widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries. It has chemical stability, high temperature resistance, good compressive strength, and is often used as a catalyst covering support material in the reactor, which can protect the catalyst and ensure the stability of the reaction.

Ceramic packing ball classification:

Ordinary ceramic packing ball: the alumina content is relatively low, the performance is more common, and the price is affordable, which is suitable for some conventional industrial applications with not particularly high performance requirements.

Aluminum porcelain ball: alumina content between ordinary porcelain ball and high aluminum porcelain ball, with a certain mechanical strength and high temperature resistance, in industrial production is also more widely used.

High aluminum porcelain ball: high alumina content, with higher hardness, strength and better high temperature resistance, suitable for high temperature, high pressure and high material performance requirements of the working environment.

Open porcelain ball: on the basis of inert alumina porcelain ball for opening treatment, increase the specific surface area and porosity, with small pressure drop, large flux characteristics, can improve the mass and heat transfer efficiency, often used in adsorption, dehydration, drying and other chemical processes.

Active porcelain ball: It is made by adding a small amount of transition metal oxide to the inert porcelain ball, which has the characteristics of high temperature resistance, high pressure and high mechanical strength of the inert porcelain ball, and has a certain catalytic activity, and plays a catalytic role in the process of olefin saturation and nitrogen removal. Microporous porcelain ball: on the basis of inert alumina ceramic ball by hole processing, the porosity is higher than ordinary porcelain ball, can filter impurities in the oil, can be used for oil purification and purification process.

Heat storage porcelain ball: with smooth surface, corrosion resistance, high strength, good heat storage performance and other characteristics, is a special filler for air separator heat storage, can store and release heat in the process of heat storage, improve energy utilization efficiency.

Ceramic packing ball action:

As a catalyst covering support material: in all kinds of hydrocracking, refining, catalytic reforming, isomerization, demethylation and other devices, ceramic packing balls are used to support the catalyst, so that the catalyst can be evenly distributed in the reactor, increase the contact area between the catalyst and the reactant, and improve the reaction efficiency. For example, in a hydrocracking unit, the catalyst, supported by ceramic packing balls, is better able to hydrocrack heavy oil and convert it into light oil. - Can protect the catalyst from poisoning and sintering, extend the service life of the catalyst. In the petrochemical production process, there may be some impurities or harmful substances, ceramic packing balls can play a certain filtering and blocking role to reduce the impact of these substances on the catalyst.

Used as tower packing: In tower equipment such as rectification tower, absorption tower, extraction tower, ceramic packing ball can increase the distribution point of gas or liquid, so that the gas-liquid two phases can more fully contact and mass transfer, improve the separation efficiency. For example, in the extraction tower of an aromatics extraction unit, ceramic packing balls can help to effectively separate aromatics from non-aromatics. Ceramic corrugated packing is a special form of ceramic packing ball, which has good corrosion resistance and separation effect, and can be applied to some corrosive processes. For example, in the transformation of sulfur-containing sewage oxidation tower of catalytic cracking unit, ceramic corrugated packing and ceramic saddle packing are used to fill, and good results have been achieved.

Used in high temperature kilns and heat exchangers: as a kind of ceramic packing ball, the thermal storage porcelain ball has the characteristics of smooth surface, corrosion resistance, high strength, good heat storage performance, etc. It can be used as a thermal storage filler for petrochemical high temperature ventilation kilns, which can store and release heat, improve energy utilization efficiency and reduce energy consumption.

Application in crude oil dehydration unit: In the process of crude oil treatment, ceramic fillers can speed up the separation of oil and water. For example, in the crude oil dehydration three-phase separator, the use of ceramic filler instead of traditional metal filler can solve the problem of easy corrosion of metal filler, ensure the quality of crude oil dehydration, and reduce the labor intensity of workers.

The main performance parameters of ceramic packing ball

Chemical composition: alumina content is an important indicator to measure the quality of ceramic packing balls, and the alumina content of different types of ceramic packing balls varies greatly.

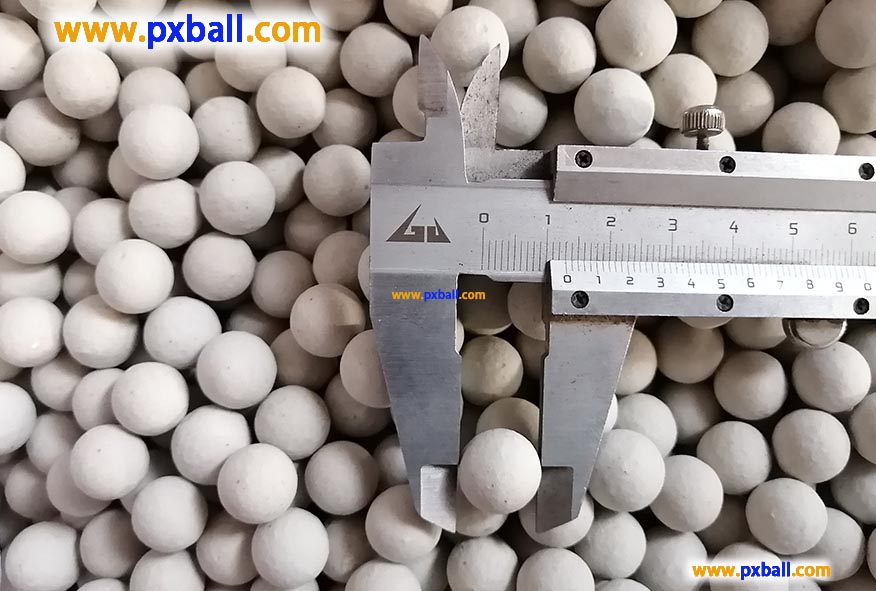

Physical properties: size and size tolerance, the size of the ceramic packing ball is usually between a few millimeters and tens of millimeters, and the common diameter is 3mm, 5mm, 10mm, 20mm, 30mm and other specifications.

Density: The density reflects the tightness and quality of the ceramic packing ball. The density of different types of ceramic packing balls is also different, such as the density of ordinary porcelain balls is relatively low, and the density of high aluminum porcelain balls is high.

Water absorption: Water absorption refers to the ability of ceramic packing balls to absorb water. The lower the water absorption rate, the better the density of the ceramic packing ball, the higher the acid resistance and strength.

Porosity: Porosity refers to the proportion of the volume of pores inside the ceramic packing ball to the total volume. The porosity will affect the strength, corrosion resistance and temperature resistance of the ceramic packing ball.

Compressive strength: Compressive strength refers to the ability of ceramic packing balls to resist damage when subjected to pressure. Because the ceramic packing ball will be subjected to the pressure and impact of the material in the reactor during use, it needs to have sufficient compressive strength.

Temperature resistance: Ceramic packing balls need to be used in high temperature environments, so temperature resistance is an important performance parameter. Different types of ceramic packing balls have different temperature resistance, in general, high aluminum porcelain balls have better temperature resistance and can be used at higher temperatures, and the temperature resistance of ordinary porcelain balls is relatively low.

Temperature resistance: Temperature resistance refers to the ability of ceramic packing balls to resist damage when the temperature changes rapidly. In practical applications, ceramic packing balls may undergo rapid heating and cooling processes, so they need to have good temperature variability to avoid cracking or crushing due to temperature changes.

ceramic packing balls

industry ceramic ball

high strength porcelain balls

china inert alumina ceramic balls

alumina packing ball

al2o3 ceramic ball

inert alumina ceramic balls

Concave convex ceramic balls