Factory Introduction

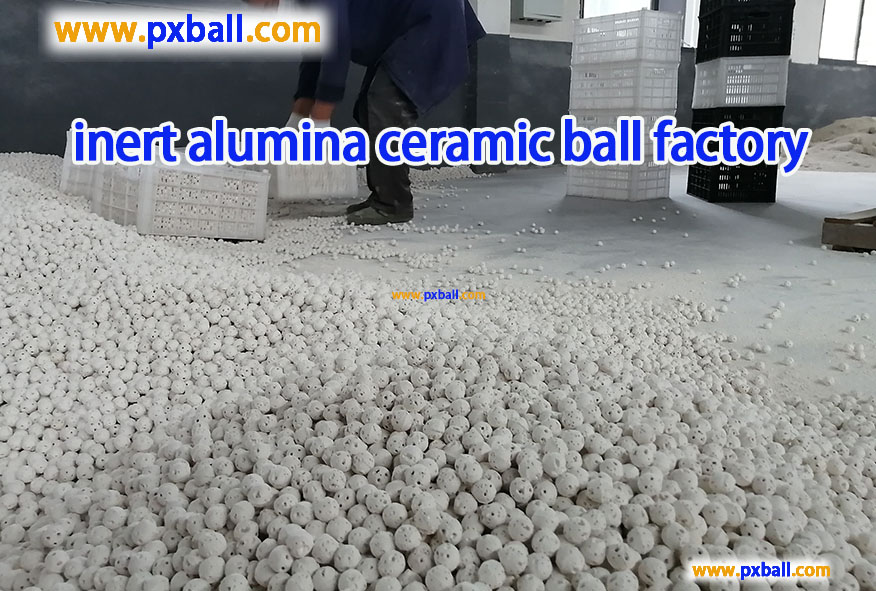

Basic Information: We are an inert alumina ceramic ball factory. We have been specializing in the production of inert alumina ceramic balls for many years. We were established in 2014 and are located in Xiangdong Ceramic Industrial Park, Pingxiang City, Jiangxi Province, China. We are an enterprise integrating production, sales and installation.

Product Categories: We mainly produce various specifications, different aluminum contents and different types of inert alumina ceramic ball products, such as low-aluminum inert ceramic balls, high-aluminum inert ceramic balls, porous inert ceramic balls, convex and concave inert ceramic balls and other series products.

Application Fields: Our products are widely used in petrochemical, coal chemical, smelting, natural gas, environmental protection and other industries.

Quality Assurance: Our inert alumina ceramic balls have strict standards and inspection procedures from raw materials, semi-finished product production to high-temperature sintering. Especially for the finished inert ceramic balls, their physical and chemical properties will be strictly inspected and qualified before being stored. Also, because we have been specializing in production for many years, the quality is more stable.

Price: As a factory-direct seller, under the premise of ensuring quality, we have a price advantage.

Price Information Notice

In order for us to provide you with an accurate quotation, please make sure to provide the following relevant information clearly

Specification and Size: The common sizes of inert alumina ceramic balls include 3mm, 6mm, 8mm, 10mm, 13mm, 16mm, 19mm, 25mm, 30mm, 40mm, and 50mm, etc.

Chemical Composition: The main component of inert alumina ceramic balls is alumina, and the content of alumina will affect the performance and price of the ceramic balls. Therefore, before quoting, it is better to clearly provide the content of tricalcium aluminate. Of course, there are other technical parameters as well.

For example, inert ceramic balls with high compressive strength can withstand greater pressure and are suitable for more demanding working conditions. Their price will be higher than that of ordinary ceramic balls with lower compressive strength.

Packaging Requirements: The packaging method and materials also affect the cost and quotation. Common packaging methods include woven bags, ton bags, wooden boxes, and iron drums. Wooden box packaging is relatively more costly, and the quotation will increase accordingly.

Order Quantity: The quantity of purchase has a significant impact on the price. Generally, the principle of "the larger the quantity, the better the price" is followed.

Delivery Time: If the customer has strict requirements for delivery time, it is necessary to clearly communicate with the factory about the time.

Delivery Location: The distance from the delivery location to the factory and the mode of transportation (such as road, railway, and sea transportation) will affect the final quotation. Contact information: Email: lizhi@pxball.cn, WeChat: pxlizhi

HS code related to inert alumina ceramic balls:

6903200090 Alumina ceramic ball

6909110090 Alumina ceramic ball

6903900090 Inert alumina ball

6914100000 Alumina corundum ceramic ball

6914900000 Alumina ceramic ball mill

6903900090 Alumina ceramic ball mill

6914100000 Inert alumina Raschig ring

6914900000 Ceramic ball

This is the year 2025.

Product Parameters

Property | Ceramic ball | Low alumina ball | Med. alumina ball | High alumina ball | Corundum ball | |

Chemical composition % | Al2O3 | 20-30 | 31-45 | 46-70 | 71-90 | >90 |

Al2O3+SiO2 | ≥90 | |||||

Fe2O3 | ≤1 | |||||

Water absorption, % | ≤5 | |||||

Acid resistance, % | ≥98 | |||||

Alkali resistance, % | ≥80 | ≥82 | ≥85 | ≥90 | ≥95 | |

Thermal shock resistance, ºC | ≥300 | ≥400 | ≥500 | ≥700 | ≥800 | |

Thermal resistance, ºC | ≥1000 | ≥1200 | ≥1300 | ≥1400 | ≥1500 | |

Crushing strength KN/grain | Φ10mm | ≥0.85 | ≥1.0 | ≥1.20 | ≥1.50 | ≥1.90 |

Φ13mm | ≥1.80 | ≥2.30 | ≥3.00 | ≥4.00 | ≥5.80 | |

Φ16mm | ≥2.30 | ≥3.00 | ≥4.50 | ≥6.00 | ≥7.00 | |

Φ20mm | ≥4.30 | ≥5.00 | ≥6.00 | ≥7.50 | ≥9.00 | |

Φ25mm | ≥6.20 | ≥7.00 | ≥8.00 | ≥10.00 | ≥12.00 | |

Φ30mm | ≥7.00 | ≥8.00 | ≥10.00 | ≥12.00 | ≥14.00 | |

Φ38mm | ≥8.80 | ≥10.00 | ≥12.00 | ≥16.00 | ≥18.00 | |

Φ50mm | ≥12.00 | ≥13.00 | ≥15.00 | ≥18.00 | ≥21.50 | |

Φ76mm | ≥16.00 | ≥18.00 | ≥20.00 | ≥22.00 | ≥25.00 | |

Bulk density, Kg/m³ | 1300-1400 | 1400-1500 | 1500-1600 | 1600-1800 | ≥1800 | |

Note: The data of bulk density is given for reference only, not as the acceptance criterion. | ||||||

Chemical Composition

Al2O3+SiO2 | Al2O3 | Fe2O3 | MgO | K2O+Na2O +CaO | Other |

> 92% | 23-26% | <1% | <2.5% | <4% | <1% |

Inert Porcelain Ball Manufacturers

Porous Ceramic Balls Factory

inert alumina ceramic ball factory

al2o3 ceramic ball factory

inert ceramic ball factory

alumina ball factory

alumina ceramic ball factory