Factory Introduction

We are a factory specializing in inert ceramic balls from China. We focus on the research and development, production, and sales of inert ceramic balls. With excellent quality and perfect services, we have established a good reputation in both domestic and international markets. From raw material selection, ingredient blending, molding to high-temperature firing, every process is strictly in accordance with international standards and industry norms to ensure the stability and consistency of product quality. Meanwhile, we also have a professional R&D team that continuously explores and innovates, dedicated to providing customers with higher-quality and more efficient inert ceramic ball product solutions.

Due to our long-term focus, the quality of inert ceramic balls is more stable. Because we are factory direct sellers, our prices are more favorable.

Contact Information

Contact Person: Li Zhi

E-mail: lizhi@pxball.cn

WeChat ID: pxlizhi

If you send us an email or a WeChat message, we will reply to your questions within 12 hours. If you need a quotation for inert ceramic balls, please specify the quantity, specifications, technical requirements, packaging method and other matters you need to purchase.

How to judge the quality

Visual inspection: For quality good inert ceramic balls, the surface should be very smooth and shiny, without obvious unevenness, bubbles, pinholes, etc. as defects.

Dimensional accuracy measurement: Use measuring tools such as calipers or micrometers to measure the diameter of the ceramic balls. Generally speaking, the diameter deviation of high-quality inert ceramic balls should be controlled within a small range, such as ±0.5mm or less, depending on the product specifications and standard requirements.

Compressive strength: Compressive strength is one of the key indicators for measuring the quality of inert ceramic balls.

Chemical performance analysis: Through chemical analysis methods, detect the content of main components such as aluminum oxide (Al₂O₃), silicon dioxide (SiO₂), etc. in the ceramic balls.

Test report and certification: Check whether the manufacturer can provide test reports issued by authoritative institutions, such as certificates of conformity issued by relevant national standards or industry standards. For example, a test report that complies with HG/T 3683.1-2000 "Industrial Ceramic Balls - Inert Ceramic Balls" standard is a powerful proof of product quality.

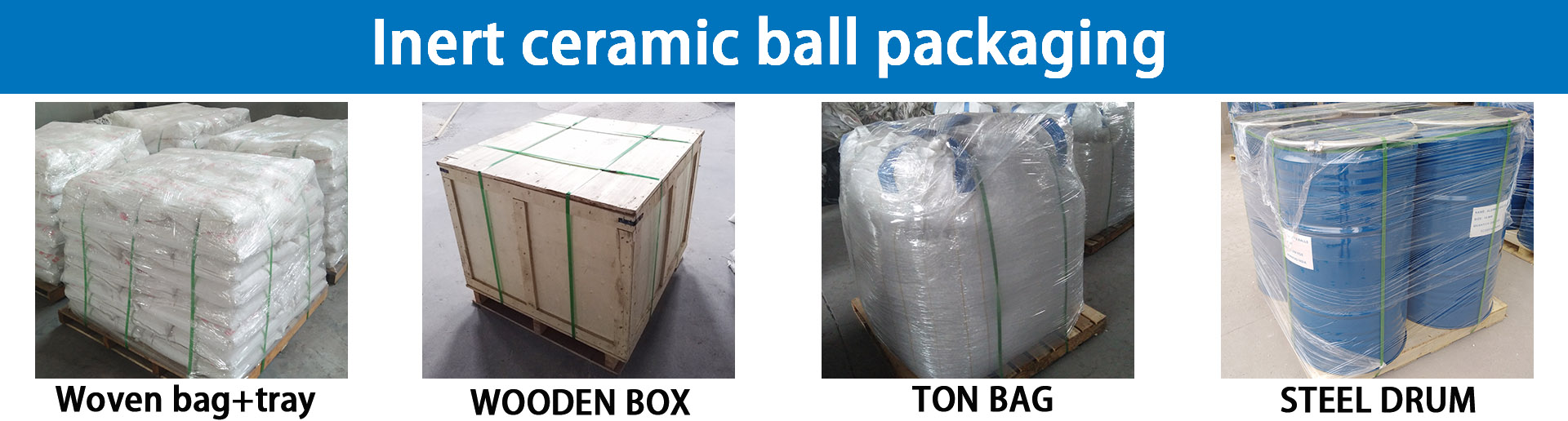

Packaging methods

The common packaging methods for inert ceramic balls for export are as follows. Different packaging methods result in significant price differences. Especially when choosing iron drums for packaging,

Inert Porcelain Ball Manufacturers

Porous Ceramic Balls Factory

inert alumina ceramic ball factory

al2o3 ceramic ball factory

inert ceramic ball factory

alumina ball factory

alumina ceramic ball factory