Application Range of 6mm Ceramic Balls

Chemical Industry: In the reactors, packing towers and other equipment used in the petroleum, chemical, fertilizer, natural gas and environmental protection industries, 6mm inert ceramic balls can be used as support and covering materials for catalysts. They can effectively buffer the impact of liquid and gas entering the reactor on the catalyst, protect the catalyst, and improve the distribution of liquid and gas in the reactor. The medium-sized size can provide sufficient support force and coverage area without causing excessive obstruction to the fluid flow in the reaction system, ensuring the efficient conduct of the reaction.

Gas Treatment: In the process of gas purification and drying, 6mm ceramic balls can be used as filler placed in adsorption towers and drying towers, used to increase the contact area and residence time of gas, and improve the effect of gas treatment. For example, in some small gas purification devices, 6mm inert ceramic balls can effectively remove impurities and moisture from gas.

Model: | Inert Ceramic Ball | |||

Color: | Light Grey | |||

Shape: | Ball | |||

Typical Technical Composition | Min.% | Max.% | Usual % | |

Si02 | 64 | 75 | 68.5 | |

Al2O3 | 23 | 26 | 24.5 | |

Fe203 | .... | 1.0 | 0.9 | |

Ti02 | .... | 0.5 | 0.46 | |

CaO | .... | 0.5 | 0.42 | |

MgO | .... | 0.5 | 0.38 | |

Na20 | .... | 2 | 1.12 | |

K20 | .... | 3.5 | 3.28 | |

AI203+Si02 | 90 | 94 | 93 | |

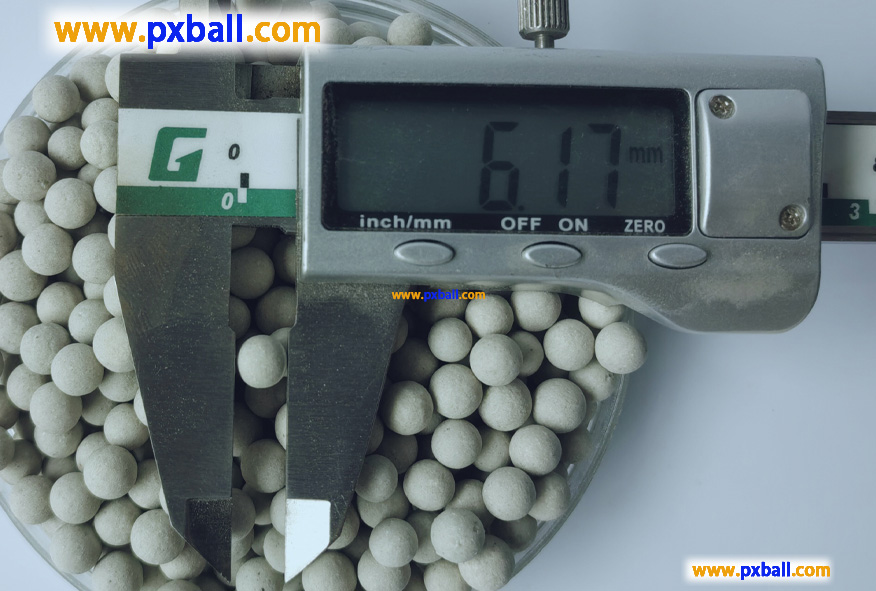

6mm Ceramic Ball Features:

Appropriate Mechanical Strength: Inert ceramic balls need to have

Why are 6mm ceramic balls used more often?

Easy to operate: The 6mm size is relatively small, making it easier to handle during filling. Whether manually filling or using mechanical filling equipment, the inert ceramic balls of 6mm can be easily filled into the equipment and ensure uniformity and tightness of the filling, thereby improving the effectiveness of the equipment.

High space utilization rate: In equipment with limited space, 6mm inert ceramic balls can better utilize space, increase the filling volume of the packing, and thereby increase the processing capacity of the equipment. For example, in some small reactors or packed towers, using 6mm inert ceramic balls can achieve better reaction or gas processing effects within limited space.

High production efficiency: During production, the production process of 6mm inert ceramic balls is relatively mature and uses mechanized production, resulting in high production efficiency and lower production costs. At the same time, due to its medium size, the waste rate in the production process is relatively lower, further improving the economic efficiency.

High cost-effectiveness: Considering its performance and price, 6mm inert ceramic balls have a high cost-effectiveness. Compared with 50mm inert ceramic balls of larger size, the price of 6mm is relatively lower, while its performance can meet the needs of most application scenarios, thus being widely welcomed in the market.

Crush Strength | ||

Size | Crush Strength | |

(kg) | (N/pc) | |

1/8"(3mm) | >55 | >0.45 |

1/4"(6mm) | >90 | >0.80 |

3/8"(10mm) | >125 | >15 |

1/2"(13mm) | >215 | >2.2 |

3/4"(19mm) | >557 | >4.97 |

1"(25mm) | >1050 | >9.5 |

1-1/2" (38mm) | >1500 | >14 |

2"(50mm) | >6600 | >66 |

What situations require replacement of 6mm ceramic balls?

1. Shape deformation:

If the ceramic balls show obvious deformation, cracking, or sharp edges, they should be replaced. Such deformed and broken ceramic balls cannot function properly in supporting and dispersing materials, and may also clog pipes, affect material flow, or damage other equipment components.

2. Decreased mechanical strength:

When the ceramic balls' mechanical strength drops to a level where they cannot withstand normal working pressure or load, they must be replaced. For example, when used as support material for catalysts, if the ceramic balls' compressive strength decreases, they may collapse under the weight of the catalyst and the fluid pressure in the reactor, leading to uneven distribution of the catalyst and affecting the reaction efficiency. The compressive strength can be tested periodically by taking samples, and if it is below 70% - 80% of the initial value, replacement should be considered.

3. Chemical corrosion:

If the ceramic balls come into contact with strong corrosive chemicals during use, they should be replaced when the ceramic balls' surface shows obvious corrosion pits or the corrosion layer thickness exceeds 5% - 10% of the ball's radius.

4. Adsorption of impurities:

When the ceramic balls adsorb a large amount of impurities, causing a

Medium Alumina Ceramic Ball

China Porous Inert Ceramic Balls

Inert Ceramic Ball Support Media

inert alumina ball

6mm ceramic ball

Best low alumina ball

Inert porcelain ball

Handmade ceramic balls