What is inert ceramic balls

Inert ceramic ball is a kind of ball made of ceramic material, mainly composed of aluminum oxide, silicon dioxide components of high strength, high temperature resistance, corrosion resistance ceramic ball.

Has the following characteristics:

1. High chemical stability: it can remain stable in most chemical environments and is not easy to react with other substances.

2. High temperature resistance: it can withstand high temperature and will not be deformed or damaged in high temperature environment.

3. High hardness: not easy to be scratched or damaged, able to withstand greater pressure and impact.

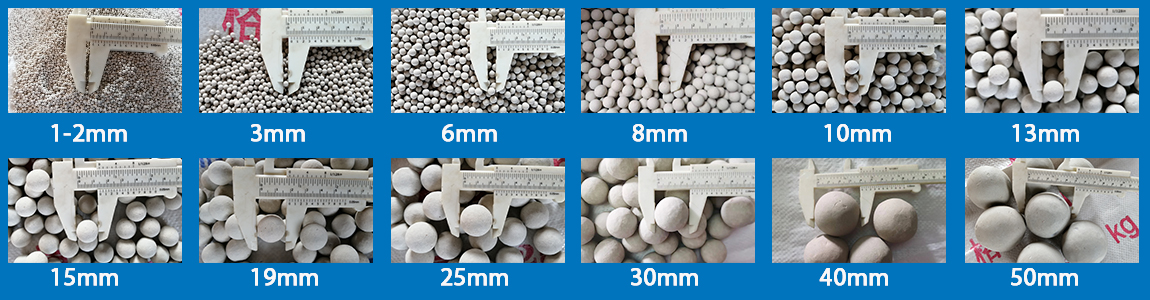

Inert ceramic ball specifications are: 3mm, 6mm, 8mm, 10mm, 13mm, 15mm, 16mm, 19mm, 20mm, 25mm, 30mm, 38mm, 50mm and other specifications can be customized production

Inert ceramic ball action

As a filler used in chemical reactors, towers and other equipment, play a supporting, dispersing and mass transfer role. For example, in the petrochemical catalytic cracking unit, the inert ceramic ball can support the catalyst, so that the reaction material can be uniformly passed through the catalyst bed, improving the reaction efficiency.

Comparison with other materials ** Compared with metal balls and plastic balls, inert ceramic balls have the following advantages:

1. Higher chemical stability: it will not be corroded by acid, alkali, salt and other chemicals, and is suitable for a variety of harsh chemical environments.

2. Better high temperature resistance: it can be used at higher temperatures, while metal balls and plastic balls may be deformed, softened or melted at high temperatures.

3 Environmental protection and non-toxic: will not release harmful substances, harmless to the environment and human health. However, inert ceramic balls also have some shortcomings, such as higher cost and greater brittleness. In practical applications, the appropriate materials need to be selected according to the specific use requirements and economic costs.

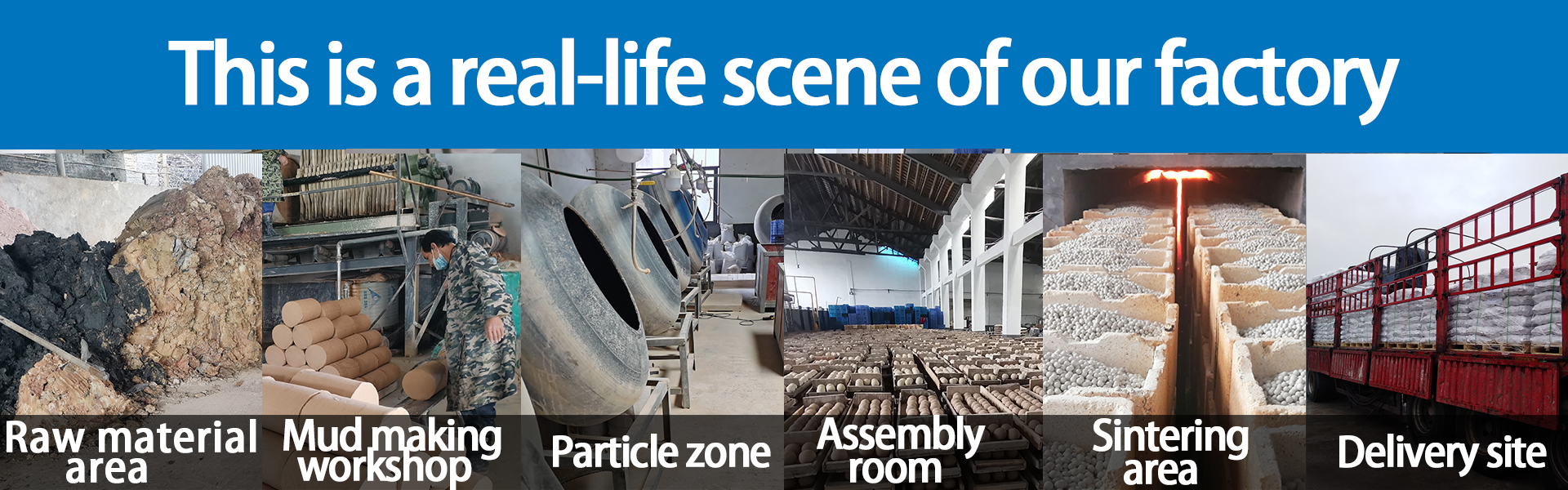

Inert ceramic ball production process:

1.** Raw material preparation ** : Select suitable ceramic raw materials, such as alumina, zirconia, silicon carbide, etc., and ensure that the purity and quality of raw materials meet the requirements.

2.** Ingredients ** : According to the formula requirements of the product, various raw materials are proportionally proportioned.

3.** Ball grinding ** : Put the prepared raw materials into the ball mill for ball grinding, so that it is fully mixed and reach the required fineness. The choice of milling time and milling medium depends on the nature of raw materials and product requirements.

4.** Sifting ** : The slurry after ball grinding is filtered through the screen to remove large particles and impurities.

5.** Filtration ** : Press the sifted slurry to form a filter cake to remove the water.

6.** Vacuum puree ** : Put the filter cake into the vacuum puree machine for vacuum puree to remove the air and bubbles and improve the density and uniformity of the mud.

7.** Stale ** : The mud after vacuum mud is put into the stale tank for stale, so that it is fully hydrated and homogenized, and improve the plasticity and molding performance of the mud. 8. ** Extruded strip ** : Put the stale mud into the extruder to extrude the strip, so that it forms a certain diameter and length of mud strip.

8.** Can be molded into balls ** : The mud strip squeezed into the ball forming machine can be molded into balls, so that it forms a certain diameter and roundness of the ball.

9.** Drying ** : The ball can be molded into a ball into the drying chamber for drying, so that it removes water, improve the strength and hardness of the ball.

10.** Box firing ** : Put the dried spheres into the Saggar box firing, so that it is sintered at high temperature to form an inert ceramic ball with a certain strength and hardness. The firing temperature and firing time depend on the type and performance requirements of the product.

11.** Inspection packaging ** : The inert ceramic ball after firing is inspected, the defective and unqualified products are removed, and then packaged for storage and transportation.

It should be noted that in the production process of inert ceramic balls, the process parameters of each link need to be strictly controlled, such as the ratio of raw materials, milling time, firing temperature and firing time, etc., to ensure that the quality and performance of the product meet the requirements. At the same time, it is also necessary to pay attention to safe production to prevent accidents.

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

What is inert ceramic ball?