How to Choose Inert Ceramic Balls

When choosing to purchase inert ceramic balls, it is necessary to consider factors such as the temperature, pressure, acidity, and alkalinity of the environment in which they will be used.

Temperature: If the reaction temperature is high, such as in petroleum cracking processes, it may reach 700-800°C, then ceramic balls with good resistance to high temperatures, such as high-alumina ceramic balls, should be chosen. Its heat resistance can reach up to 1650°C and can maintain the stability of physical and chemical properties in high-temperature environments, avoiding the deformation, breakage or unfavorable reaction of the ceramic balls with the catalyst and affecting production.

Pressure: For reactions that take place under high pressure, such as hydrogen refining, the pressure is usually between 4-10MPa or even higher. Ceramic balls with high mechanical strength and compressive strength should be selected to withstand the high-pressure environment and prevent the ceramic balls from breaking, ensuring the stability and integrity of the catalyst during the reaction process.

Acid-base degree: In chemical reactions involving acidic or basic substances, such as in certain fertilizer production processes where acidic or basic gases or liquids may be encountered, ceramic balls with high chemical stability and resistance to acid and alkali corrosion, such as inert alumina ceramic balls made of high-quality chemical clay materials, can withstand the corrosion of acid, alkali and other solvents. This can ensure that the carrier is not corroded in a corrosive environment and maintain the activity of the catalyst.

Molecular size and shape:If the reactant molecules are larger, it is necessary to choose inert ceramic balls with larger pore structures and uniform distribution, so that the reactant molecules can enter the interior of the ceramic balls smoothly and fully contact the catalyst loaded on its surface and pores, thereby improving the reaction efficiency. For example, in the catalytic cracking reaction of petroleum macromolecules, the larger pore structure is conducive to the adsorption and reaction of petroleum macromolecules on the catalyst active sites.

Chemical activity: If the reactants or products have strong chemical activity and are prone to react with other substances, it is necessary to ensure that the inert ceramic balls used do not react with them chemically, to avoid affecting the selectivity of the reaction and the activity of the catalyst. For example, in some organic synthesis reactions, it is necessary to use inert ceramic balls with extremely high chemical inertness to ensure that the reaction proceeds as expected and reduce the occurrence of side reactions.

Advantages of Inert Ceramic Balls:

1. Corrosion Resistance: Have an extremely strong resistance to chemicals such as acids, bases, and salts. They can maintain their original properties in strong corrosive environments, and are unlikely to react chemically with reactants or products, ensuring the catalyst activity and stability of chemical production. For example, in the hydrogenation refining reaction of petroleum, there are corrosive substances such as hydrogen sulfide, and the inert ceramic ball carrier will not be corroded, while the metal carrier may be corroded, affecting the catalyst performance.

2. Oxidation Resistance: Are resistant to oxidation in high temperatures and oxygen environments, and can maintain their chemical properties stable for a longer period of time. They are suitable for chemical reactions that require high temperatures and oxygen participation, such as certain high-temperature oxidation reactions. However, carbonized silicon carbide and other carriers may be oxidized in oxygen atmosphere.

3. High Thermal Stability: Can withstand high temperatures, generally can tolerate temperatures above 1000℃, and some can even reach 1650℃. They are also less likely to crack or deform under sudden temperature changes, ensuring the stability and service life of the catalyst in high-temperature chemical reactions. For example, in the cracking reaction of petroleum, the inert ceramic ball carrier will not soften or deform under high temperatures, while some organic high-molecular weight carriers may decompose and fail at high temperatures.

4. High Mechanical Strength: Have extremely high compressive strength and hardness, can withstand large pressure and impact, and are less likely to wear or break. They can maintain their structural integrity under strict operating conditions, such as high pressure and high fluid velocity, ensuring the stability and even distribution of the catalyst in the reactor. For example, in fluidized bed reactors, the inert ceramic ball carrier can withstand collisions between particles and the washing of fluid, while glass beads and other carriers may break due to collisions.

5. Large Specific Surface Area: Can provide more loading sites for the catalyst, allowing the active components of the catal

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

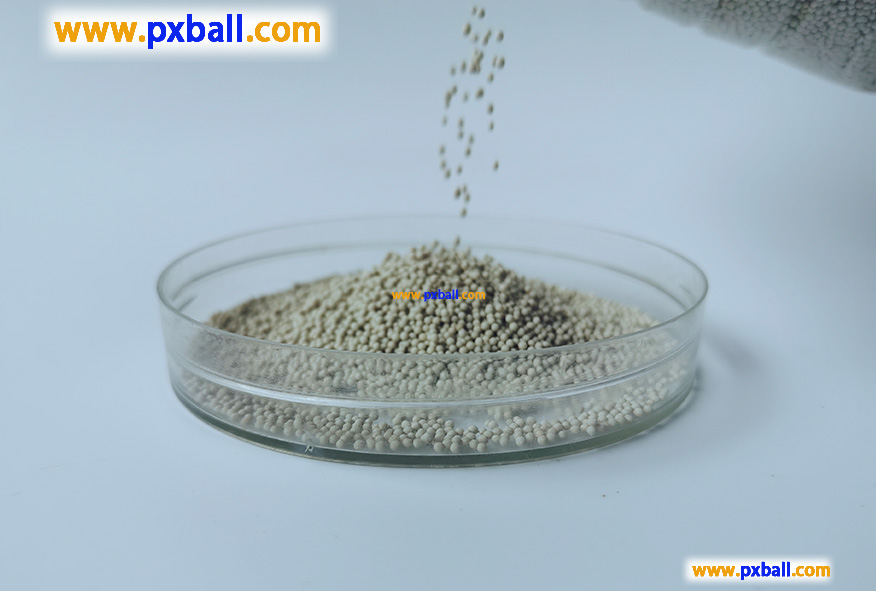

What is inert ceramic ball?