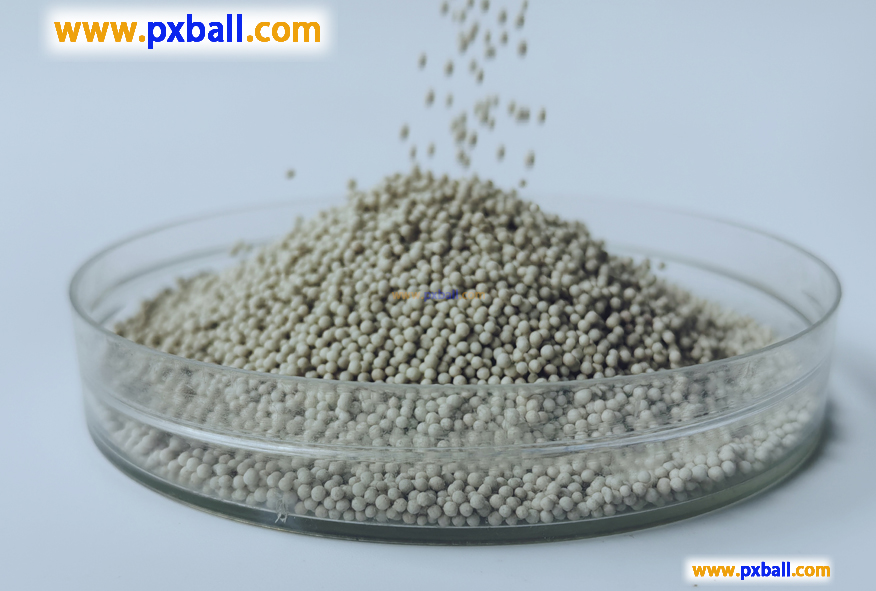

Ceramic ball in the industrial field can be used as a grinding medium for material grinding, in bearings and other mechanical parts as a rolling body to improve wear resistance, in the medical aspect can be used in some medical devices, in the chemical field is also widely used, such as acting as a catalyst carrier.

The applications of ceramic balls are as follows:

1. Bearing components in mechanical engineering: widely used in high-speed precision bearings, and are a key component in hybrid ceramic ball bearings.

2. Grinding media: due to its high hardness and good wear resistance, it can be used as a grinding medium for grinding and mixing various powder materials, which can improve grinding efficiency and product quality. It is widely used in the grinding processing process of pigments, paints, inks, ceramic materials and other industries.

3. Liner of reaction vessel in chemical industry: can be used as the liner material of the reaction vessel, such as sulfuric acid reaction vessel and phosphoric acid reaction vessel. Because of its corrosion resistance and high-temperature stability, it can significantly improve the service life and reliability of the equipment.

4. Catalyst carrier: its low friction coefficient and high mechanical strength can ensure the stability and activity of the catalyst, making it suitable for use as a catalyst carrier in various chemical reactions.

5. And other applications: filter materials, aerospace field, new energy vehicle field, electronic field, medical field, etc.

Ceramic balls are classified according to their use:

Grinding ceramic balls: These ceramic balls are mainly used in various grinding equipment as grinding media to grind and crush materials. For example, alumina ceramic balls are commonly used in the grinding processing of cement, ceramics, chemicals, pigments, paints, etc.

Bearing ceramic balls: Used to manufacture ceramic ball bearings, which require high precision, high hardness, high wear resistance, and low friction coefficient to meet the bearing's use requirements in high-speed, high-precision, high-temperature, and corrosive working environments. Common examples include silicon nitride ceramic ball bearings and zirconia ceramic ball bearings.

Catalyst carrier ceramic balls: As a carrier for the catalyst, it needs to have a large specific surface area and good chemical stability so that the catalyst can be evenly dispersed on its surface to improve the efficiency of the catalytic reaction. For example, inert alumina ceramic balls can be widely used as catalyst carriers in the petroleum, chemical, fertilizer, natural gas, and environmental protection industries.

Catalyst support ceramic balls: Used as a support for the catalyst in various reactors and towers, to play a supporting, dispersing, and filtering role, such as perforated ceramic balls, single-hole ceramic balls, and multi-hole ceramic balls.

The common specifications range of ceramic balls are as follows:

1. **Micro-sized**: The diameter can be as small as around 0.5 mm, suitable for some extremely precise applications with limited space in micro-mechanical, electronic devices, etc. Such as some micro bearings, chip encapsulation in electronic devices. - There are also common specifications of ceramic balls with diameters of 0.7 mm, 0.8 mm, etc., which are often used in small precision instruments or equipment with strict requirements on component size.

2. **Conventional sizes**: Ceramic balls with diameters ranging from 3 mm to 30 mm are widely used. For example, ceramic balls with diameters of 6 mm, 10 mm, 15 mm, 20 mm, etc. can be used in various types of ordinary bearings, grinding equipment, mechanical seals, etc. - Ceramic balls of this size range are often used as fillers or catalyst carriers in reactors and towers in the chemical and petroleum industries.

3. **Larger sizes**: Large ceramic balls with diameters of 50 mm or more are relatively less common, but are still used in some large mechanical equipment, special projects, or specific industrial applications. For example, some large ball mills, large chemical reactors, etc. may use larger ceramic balls as grinding media or support components according to their needs. - Additionally, larger ceramic balls may be used in some special sports equipment and crafts, but such applications are relatively specialized.

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

What is inert ceramic ball?