What are the properties of alumina balls?

Alumina ball performance and quality testing standards include many aspects. Appearance quality, dimensional deviation, A12O3 content, water absorption and compressive strength, and temperature resistance.

Alumina content: Alumina ball according to the content of feldspar, feldspar-mullite, mullite, mullite - corundum, corundum and other different materials.

Inert porcelain balls should be accepted by batch, 50 tons of products of the same specification made under the same raw materials, processes and equipment as a batch, less than 50 tons is also calculated by a batch.

Alumina ball compressive strength: compressive strength: compressive strength test on the test machine, the average compressive strength is [specific value] MPa, much higher than the minimum value specified in the standard, the value of the inert porcelain ball compared with the industry standard to determine whether it is qualified.

Bulk density: Measured by [specific measurement method], the bulk density is [specific value] kg/m³, which meets the requirements of product design.

Appearance quality inspection:

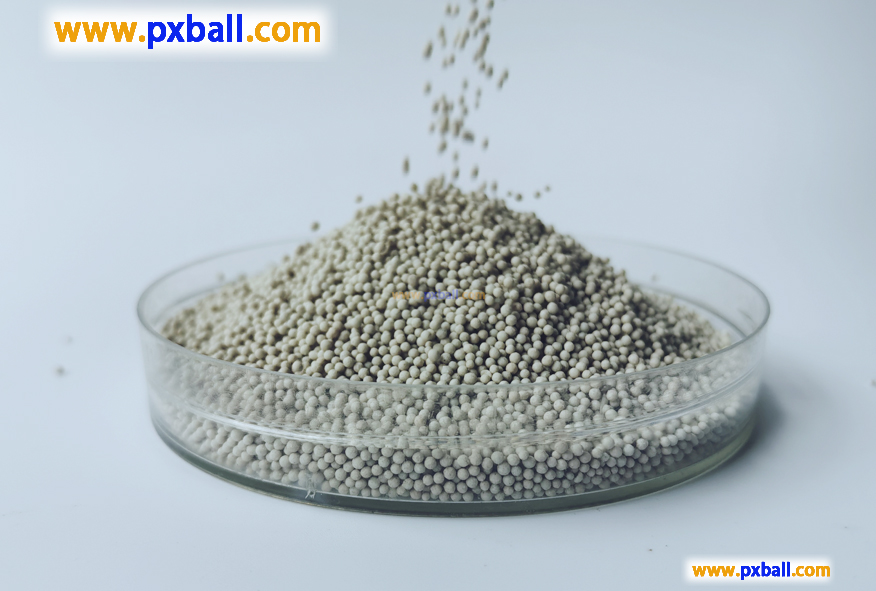

Color: Porcelain ball color is uniform, pure white, no obvious color difference or color spots.

Surface flatness: the surface is smooth and flat, no cracks, bubbles, bumps and uneven defects.

Impurities: After inspection, no obvious impurities were found.

Alumina ball temperature rapid change performance: the porcelain ball in the [high temperature temperature value] and [low temperature temperature value] between the [specific number] of acute cooling and acute heating cycle, no cracks or crushing phenomenon was found, excellent temperature rapid change performance.

Alumina content classification of inert porcelain balls

Inert alumina porcelain balls according to the different alumina content, can be divided into ordinary porcelain balls, aluminum porcelain balls, high aluminum porcelain balls and corundum porcelain balls. The higher the alumina content, the better the alkaline resistance and the higher the compressive strength.

Technical requirements for inert alumina porcelain balls in hydrogen peroxide project

In the hydrogen peroxide project, there are strict technical requirements for the performance of inert porcelain balls. For example, the main performance parameters of inert porcelain balls for hydrogen peroxide devices provided by Party B include main crystal phase, appearance, AL2O3 content, pile density, wear, water absorption, acid resistance, alkali resistance, temperature change resistance, Fe2O3 content, compressive strength, etc. There are clear indicators.

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

What is inert ceramic ball?