alumina ceramic balls manufacturers in india

There are actually many Indian alumina ceramic ball manufacturers who import inert alumina ceramic balls from China, so here we provide information on Chinese alumina ceramic ball manufacturers.

Contact Information of Chinese Exporter of Alumina Ceramic Balls to India

Email:lizhi@pxball.cn

WeChat:pxlizhi

Phone:+86-1397913701

The Manufacturer of Alumina Ceramic Balls

We are a professional manufacturer of alumina ceramic balls with many years of experience. Because we are professional, our quality is more stable. Because we are manufacturers, our prices are more reasonable. We have multiple patents and various honors for alumina ceramic balls. Our products have passed the ISO9000 system certification. Our factory has its own testing equipment and R&D team.

Things to Note When Purchasing Alumina Ceramic Balls(alumina ceramic balls manufacturers in india)

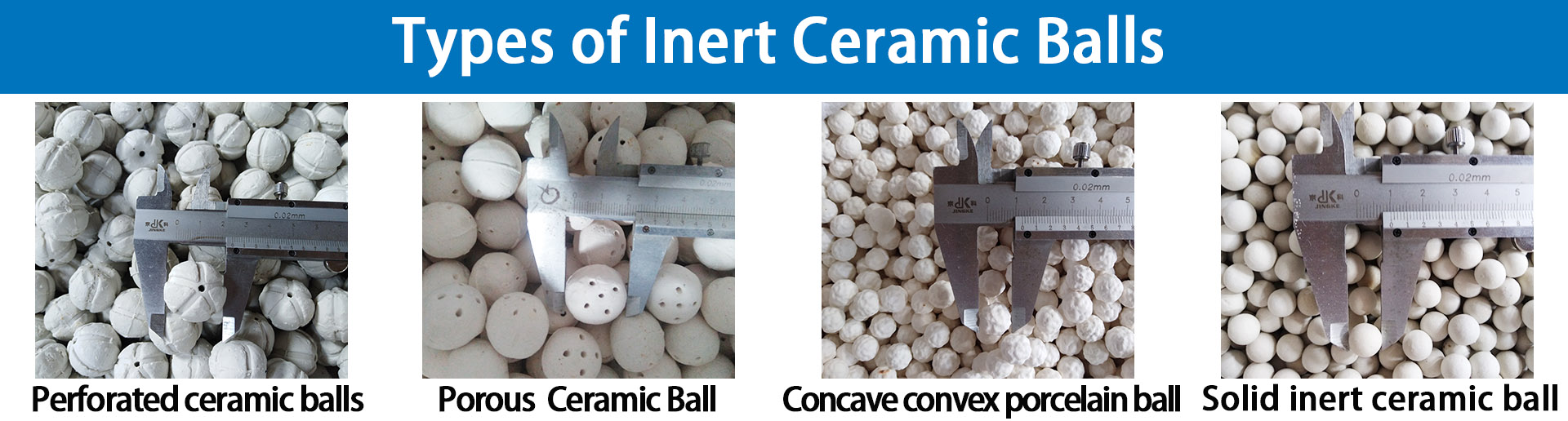

Appearance Quality: High-quality alumina ceramic balls should have a smooth surface, no cracks, no pores, and no obvious defects.

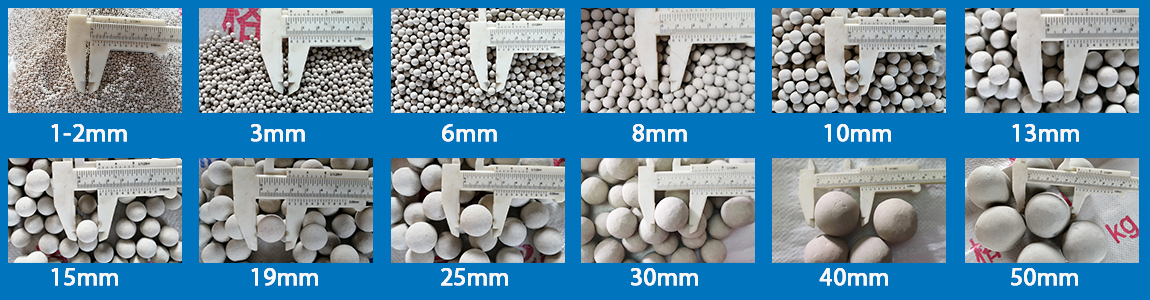

Dimensional Accuracy: The dimensional tolerance should be within the allowable range, which can be measured using tools such as vernier calipers.

Chemical Properties: The oxide aluminum content should be checked to see if it meets the requirements. High-purity alumina ceramic balls have better chemical stability, wear resistance, and high-temperature resistance.

Physical Properties: Including density, hardness, and compressive strength. Higher hardness means better wear resistance, allowing the balls to withstand prolonged grinding without wear; High compressive strength ensures that the balls will not break under pressure.

Indian manufacturers of alumina ceramic balls can refer to the following standards:

(alumina ceramic balls manufacturers in india)

The industrial ceramic ball standard HG/T 3683.1-2014 "Industrial Ceramic Balls - Inert Ceramic Balls" applies to inert alumina ceramic balls. The standard specifies requirements for the material, technical indicators, chemical composition, etc. of inert alumina ceramic balls. For example, the water absorption rate is less than or equal to 5%, the acid resistance is greater than or equal to 98%, the alkali resistance is greater than or equal to 80%-95%, and the high temperature resistance is greater than or equal to 1300-1700°C; for different types of inert alumina ceramic balls, there are corresponding regulations on the content of alumina, such as feldspar-based containing Al2O3: 20-30%, corundum-based containing Al2O3 ≥90%.

The role of alumina ceramic balls:

In the chemical industry: can be used in packing towers, packing beds, etc. Its high specific surface area and porosity can provide a larger contact area, enhance the efficiency of material transfer, for example, in distillation towers and absorption towers in the petrochemical industry, alumina ceramic balls as packing material can improve the separation efficiency and processing capacity of the tower.

Used as a catalyst carrier: In a chemical reaction, a catalyst needs a carrier to support and disperse it to improve the catalyst's activity and stability. Alumina ceramic balls, with their stable chemical properties, high temperature resistance, and acid and alkali corrosion resistance, are very suitable as a carrier for catalysts. For example, in the catalytic cracking and hydrogen refining processes in the petrochemical industry, alumina ceramic balls carry the catalyst and participate in the chemical reaction to improve the efficiency and selectivity of the reaction.

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

What is inert ceramic ball?