What is a porcelain ball

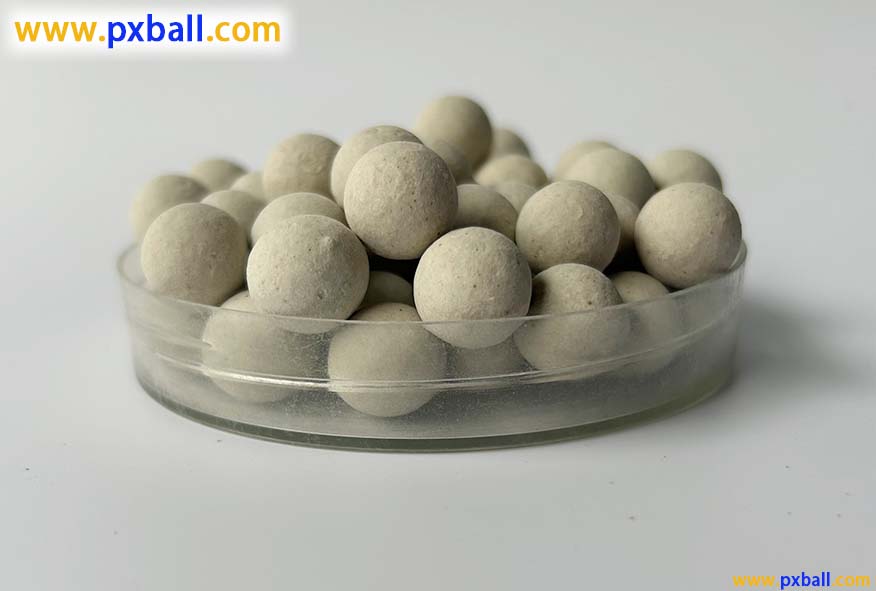

Ceramic balls are spherical fillers mainly made of alumina, zirconia, and other materials, which are fired at high temperatures.

1、 Characteristics of porcelain balls

high strength

Ceramic balls have high mechanical strength, can withstand large pressures and impacts, and are not easily broken or worn in various industrial equipment.

This makes ceramic balls widely used in reactors, towers, and other equipment in industries such as chemical, petroleum, and metallurgical, ensuring long-term stable operation of the equipment.

High hardness

The hardness of ceramic balls is relatively high, second only to diamond. This makes it have good wear resistance and corrosion resistance, and can be used for a long time in harsh working environments.

For example, in some corrosive media, ceramic balls can resist chemical erosion and maintain their physical properties and shape unchanged.

High temperature resistance

Ceramic balls can withstand high temperature environments and can generally be used at temperatures above 1000 ℃. This makes it of significant application value in high-temperature industries such as ceramics, glass, steel, and others.

In high-temperature reactors, kilns, and other equipment, ceramic balls can be used as fillers or support materials to provide insulation, heat preservation, and support.

Good chemical stability

Ceramic balls have good chemical stability and are not prone to chemical reactions with other substances. It exhibits excellent corrosion resistance in corrosive media such as acid, alkali, and salt.

This enables ceramic balls to be used in the fields of chemical engineering, environmental protection, etc. to treat various corrosive substances such as acids, alkalis, organic solvents, etc.

2、 Classification of Ceramic Balls

Classified by purpose

Grinding ceramic balls: mainly used for grinding and crushing various materials, such as ores, cement, ceramic raw materials, etc. Grinding ceramic balls have high hardness and wear resistance, which can effectively improve grinding efficiency and product quality.

Filler ceramic balls: mainly used to fill various reactors, towers and other equipment, playing a role in support, dispersion and mass transfer. Filler ceramic balls have good physical properties and chemical stability, which can meet the needs of different industrial fields.

Inert ceramic balls: mainly used in reactors in chemical, petroleum and other industries as carriers or support materials for catalysts. Inert ceramic balls have the characteristics of good chemical stability, high thermal stability, and high mechanical strength, which can ensure the activity and stability of catalysts.

Classified by Material

Aluminum oxide ceramic ball: made mainly of aluminum oxide, it has the characteristics of high hardness, high strength, high temperature resistance, corrosion resistance, etc. Aluminum oxide ceramic balls are widely used in industries such as chemical, petroleum, and metallurgy.

Zirconia ceramic ball: made mainly of zirconia, it has higher hardness and strength, as well as good wear resistance and corrosion resistance. Zirconia ceramic balls are mainly used in high-end fields such as electronics, aerospace, etc.

Silicon carbide ceramic ball: Made mainly of silicon carbide, it has extremely high hardness and strength, as well as good thermal conductivity and corrosion resistance. Silicon carbide ceramic balls are mainly used in industrial equipment under harsh environments such as high temperature, high pressure, and strong corrosion.

3、 Application fields of ceramic balls

Chemical industry

In chemical reactors, ceramic balls can serve as fillers to support catalysts, disperse gas streams and liquids, and improve reaction efficiency and product quality.

Ceramic balls can also be used for insulation, heat preservation, and corrosion prevention of chemical equipment, extending the service life of the equipment.

Oil industry

In the process of petroleum refining, ceramic balls serve as carriers or support materials for catalysts, ensuring their activity and stability, improving refining efficiency and product quality.

Ceramic balls can also be used for anti-corrosion and wear-resistant purposes in petrochemical equipment, reducing maintenance and replacement costs.

Metallurgical industry

In the metallurgical industry, ceramic balls can be used as fillers or supporting materials for high-temperature reactors, kilns, and other equipment, playing a role in insulation, heat preservation, and support.

Ceramic balls can also be used for wear and corrosion resistance of metallurgical equipment, improving the service life and production efficiency of the equipment.

Environmental Protection Industry

In the field of environmental protection, ceramic balls can be used as fillers or filtering materials in equipment such as sewage treatment and exhaust gas treatment, playing a role in adsorption, filtration, and purification.

Ceramic balls can also be used for anti-corrosion and wear-resistant of environmental protection equipment, ensuring the long-term stable operation of the equipment.

In short, ceramic balls are spherical fillers with high strength, high hardness, high temperature resistance, and good chemical stability, widely used in industries such as chemical, petroleum, metallurgy, and environmental protection. With the continuous advancement of technology and the continuous development of industry, the application fields of ceramic balls will become increasingly widespread.

Catalyst Inert Ceramic Packing Process

Is ceramic an inert waste?

Are ceramics chemically inert?

What is inert ceramics?

inert alumina ceramic ball density

Why do inert ceramic balls emphasize the level of aluminium content?

What are alumina ceramic balls used for?

What is inert ceramic ball?